Description

HU/HUC hangers may be installed on a masonry/concrete wall as described below. Additionally, HU hangers with one flange concealed may be installed similarly.

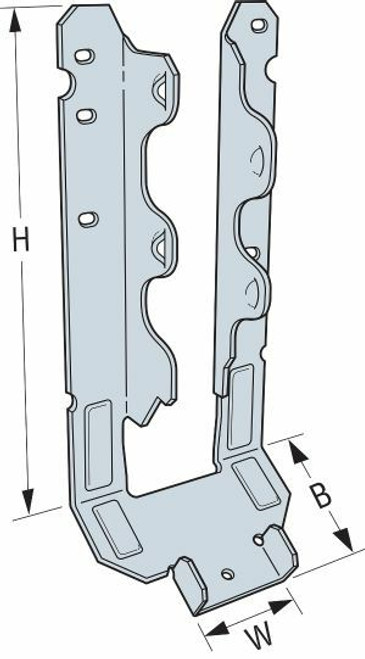

HU and HUC products are heavy-duty face-mount joist hangers made from 14-gauge galvanized steel.

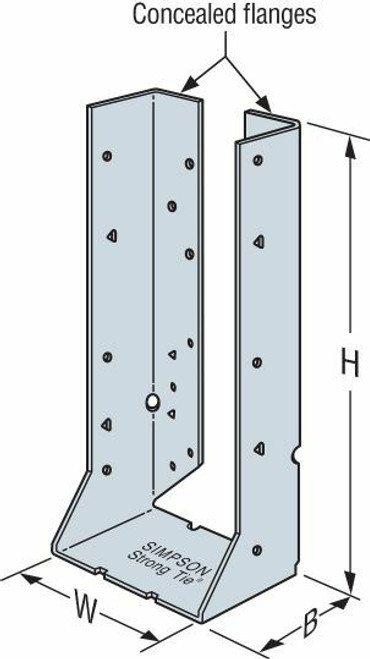

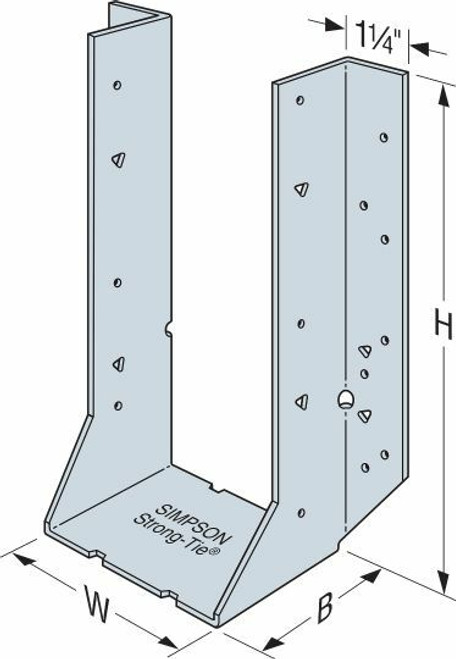

- The HUC is a concealed flange (face flanges turned in) version of the HU.

- HU is available with both flanges concealed, provided the W dimension is 2 5/16" or greater, at 100% of the table load. Specify HUC.

- HU is available with one flange concealed when the W dimension is less than 2 5/16" at 100% of the table load. Specify as an 'X' version and specify flange to conceal.

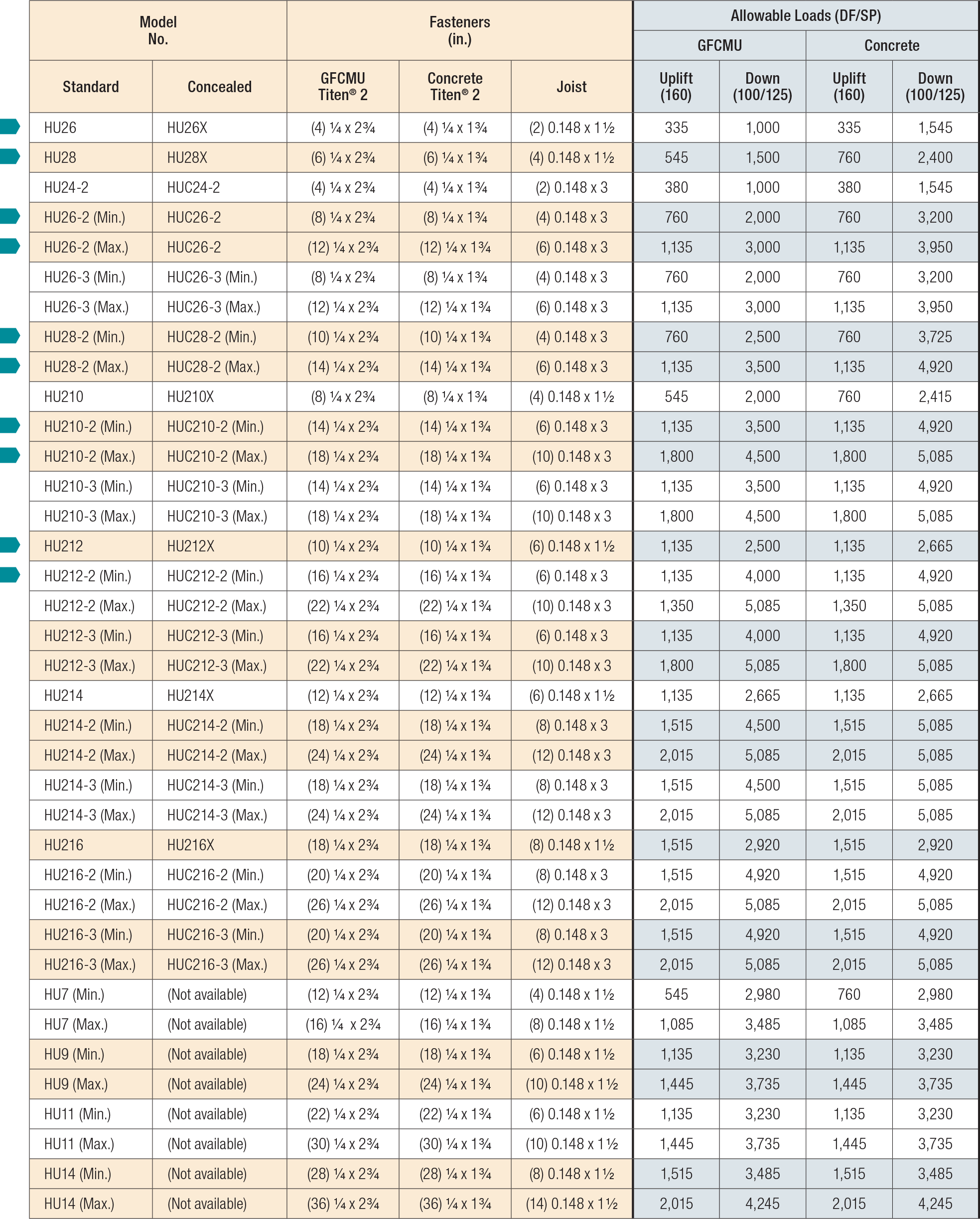

- For any HU or HUC shown in this catalog, the user may substitute all face nails with 1/4" x 1 3/4" Titen® 2 screws (model TTN2-25134H) for concrete and 1/4" x 2 3/4" Titen 2 screws (model TTN2-25234H) for GFCMU. Follow all installation instructions and use the table loads from the sawn lumber or EWP tables.

Material

- 14 gauge

Finish

- Galvanized; ZMAX® and stainless steel available

Installation

- Attach the hangers to concrete or GFCMU walls using hex-head Titen 2 screws. Titen screws for GFCMU (1/4" x 2 3/4" — model TTN2-25234H) and for concrete (1/4" x 1 3/4" — model TTN2-25134H) are not provided with the hangers.

- Drill the 3/16"-diameter hole to the specified embedment depth plus 1/2".

- Alternatively, drill the 3/16"-diameter hole to the specified embedment depth and blow it clean using compressed air.

- Caution: Oversized-diameter holes in the base material will reduce or eliminate the mechanical interlock of the threads with the base material and will reduce the anchor’s load capacity.

- Titen Installation Tool Kits are available. They include a 3/16" drill bit and hex-head driver bit (model TTNT01-RC); a 3/16" x 4 1/2" drill bit is also available (model MDB18412).

- A minimum edge distance of 1 1/2" and minimum end distance of 3 7/8" is required. See installation image "HUC410 Installed on Masonry Block End Wall" in image gallery.

- Where no uplift load is required, a minimum end distance of 1 1/2" is permitted.

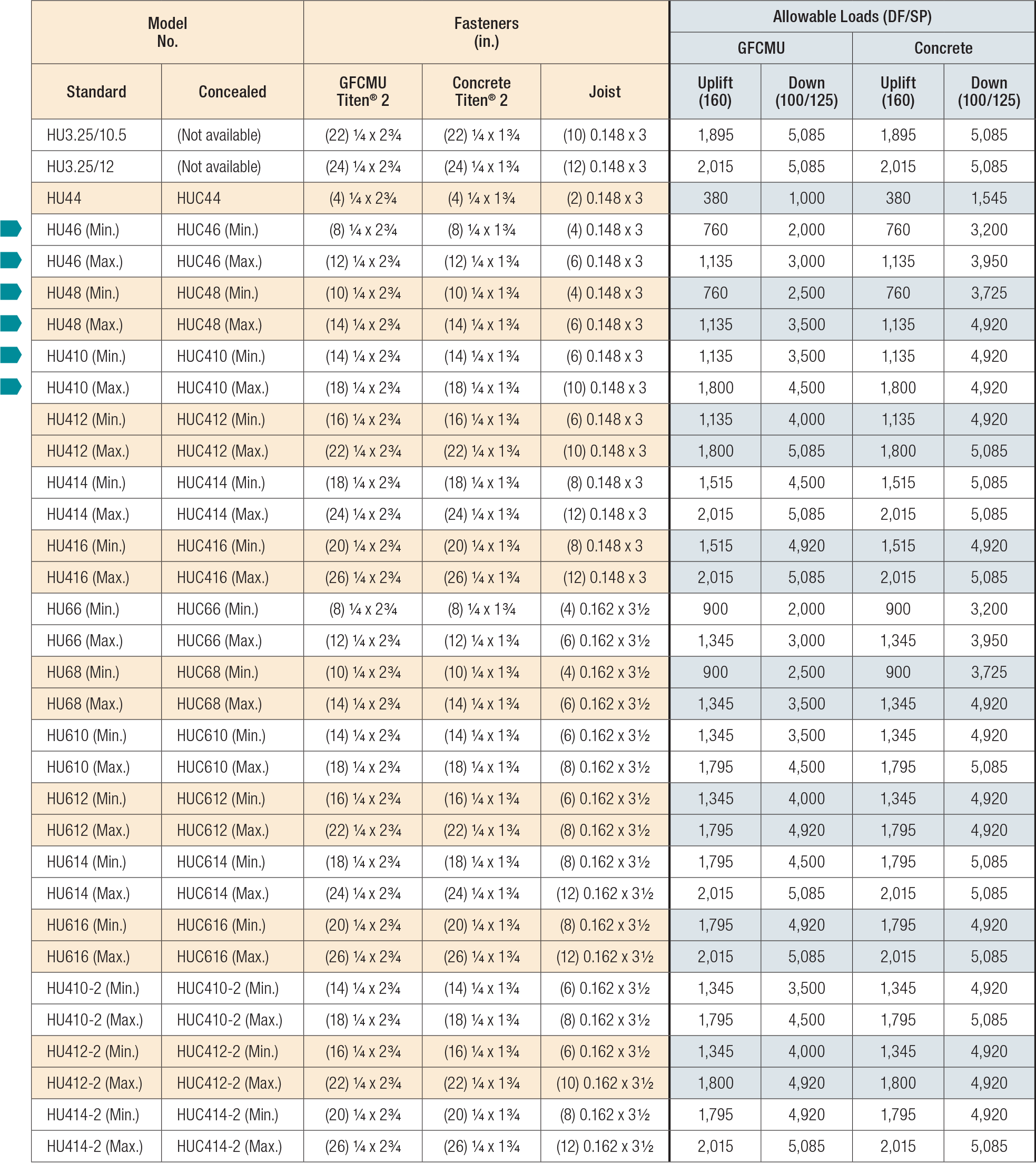

Load Tables

These products are available with additional corrosion protection. Additional products on this page may also be available with this option, check with Simpson Strong-Tie for details.

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Concrete shall have a minimum compressive strength of f'c = 2,500 psi.

- Grout-filled CMU (GFCMU) shall have a minimum compressive strength of f'm = 1,500 psi.

- When only one flange is concealed, specify whether the right or the left is the concealed flange.

- Products shall be installed such that Titen® screws are not exposed to the weather.

- Fasteners: Nail dimensions in the table are diameter by length. Titen 2 screws are Simpson Strong-Tie masonry screws. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

Extra Information

Brand:

Simpson Strong-Tie

Weight:

1.30 LBS