Description

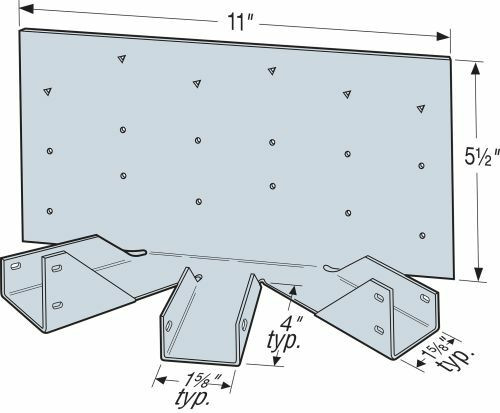

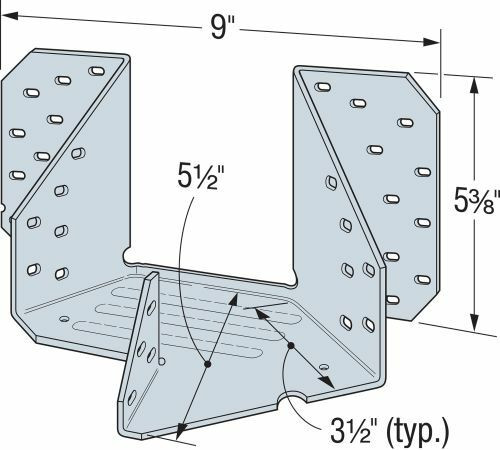

The MTHMQ and MTHMQ-2 are designed for carrying two or three trusses. The design offers concealed flanges and installs with Strong-Drive® SDS Heavy-Duty Connector screws for easier installation.

Key Features

- Accommodates right- or left- hand hips (at 45° skews) and terminal hips with or without the center jack

- Strong-Drive SDS Heavy-Duty Connector screws (included) are easy to install and enable the hangers to achieve higher loads with fewer fasteners

- Concealed-flange design allows for attachment to vertical web members

- Min. and max. fastening options for added versatility

Material

- 12 gauge

Finish

- Galvanized (G90)

Installation

- Use all specified fasteners; see General Notes.

- Can be installed filling round holes only, or filling round and triangle holes for maximum load. For all installations, fill the fastener holes in the bottom of the hanger seat.

- For installations at panel points with 2x6 bottom chords, do not fill the triangle holes unless approved by the Truss Designer.

Load Tables

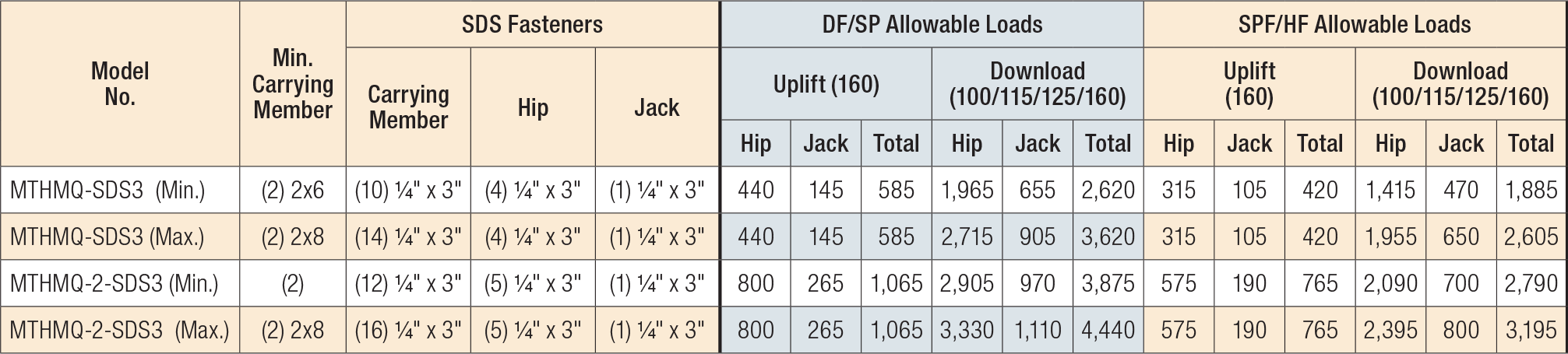

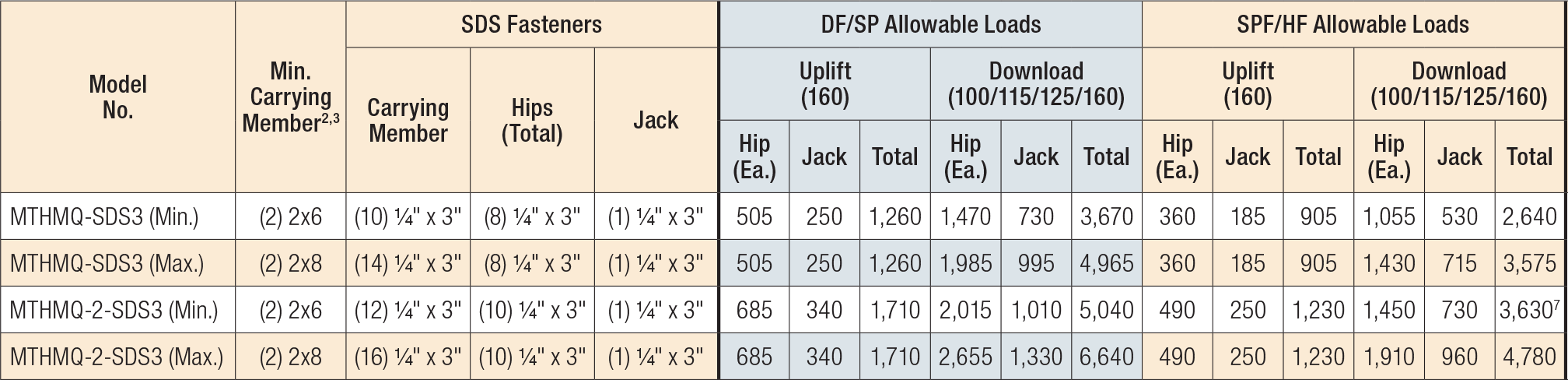

Terminal Type Installation (Three-Member Connection)5

- Allowable loads have been increased for wind or earthquake loading with no further increase allowed. Reduce where other loads govern.

- A minimum two-ply carrying member is required for the tabulated loads. With single 2x carrying members, use 1/4" x 1 1/2" Strong-Drive® SDS Heavy-Duty Connector screws in the carrying member and reduce the load to 0.60 of the table value.

- For installations on 2x6 carrying members not at a panel point, the four uppermost face fasteners are not installed. For installations on 2x6 carrying members at a panel point, fasteners are installed into the round holes only (minimum vertical member sizes are 2x6 and 2x8 for the MTHMQ and MTHMQ-2, respectively).

- Tabulated two-member allowable loads assume that 75% of the total load is distributed to the hip and 25% to the jack. It is permitted to distribute 65% to 85% of the tabulated total load to the hip, and the remaining percentage of total load to the jack. The combined hip and jack load may not exceed the published Total Load.

- For terminal hips, divide the total allowable load by 2 to determine the allowable load for each hip.

- Tabulated three-member loads assume that each hip carries 40% of the total load and the jack carries 20% of the total load. Other hip-jack load distributions are allowed if the load sum for all three carried members does not exceed the total load and the hip members are equally loaded.

- Where noted in the table, the total allowable download for the MTHMQ-2-SDS3 (min.) for a three-member connection at the 115/125/160 load duration is 5,400 lb. (DF/SP) and 3,890 lb. (SPF/HF).

- Truss chord cross-grain tension may limit allowable loads in accordance with ANSI/TPI 1-2014. Simpson Strong-Tie® Connector Selector® software includes the evaluation of cross-grain tension in its hanger allowable loads. For additional information, contact Simpson Strong-Tie.

- Strong-Drive® SDS Heavy-Duty Connector screws may be installed through metal truss plates as approved by the Truss Designer, provided the requirements of ANSI/TPI 1-2014, Sections 7.5.3.4 and 8.9.2 are met (predrilling required through the plate using a 5/32" bit maximum).

Extra Information

Brand:

Simpson Strong-Tie

Weight:

3.50 LBS