Description

Designed to provide an easy-to-install, high-strength alternative to through-bolting and traditional lag screws. The Strong-Drive SDWS Timber Screw (Exterior Grade) is ideal for the contractor and do-it-yourselfer alike. It is code listed under IAPMO UES ER-192 and meets 2015 and 2018 IRC® and IBC® code requirements for several common wood framing applications.

Key Features

- SawTooth™ point ensures fast starts, reduces installation torque and eliminates the need for predrilling in most applications

- Bold thread design provides superior holding power

- Underhead nibs offer greater control when seating the head

- Large low-profile washer head provides maximum bearing area (0.75" head dia.)

- Size identification on all SDWS screw heads

- 6-lobe T40 drive provides positive engagement that makes the screw easy to drive and improves bit life (replacement driver bit — BIT40T-134-RC)

- U.S. Patent 9,523,383

Double-barrier coating provides corrosion resistance equivalent to hot-dip galvanization, making it suitable for certain exterior and preservative-treated wood applications, as described in the evaluation report.

Applications

- Structural wood-to-wood/engineered including ledgers; mass timber connections including CLT wall-to-wall, floor-to-floor, surface splines and lap joints

Product Includes

- Retail and mini-bulk packs include one 6-lobe, T40 driver bit; bulk packs include two driver bits

Load Tables

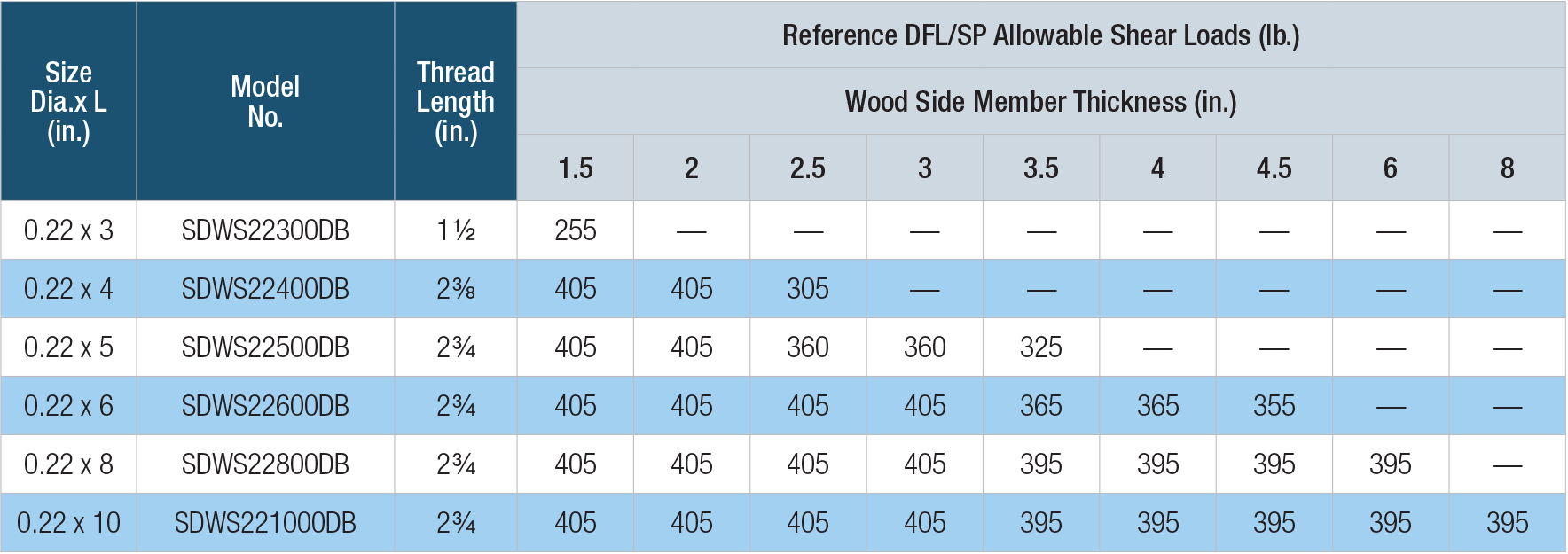

SDWS Timber Screw (Exterior Grade) — Allowable Shear Loads — Douglas Fir–Larch and Southern Pine Lumber

See footnotes below.

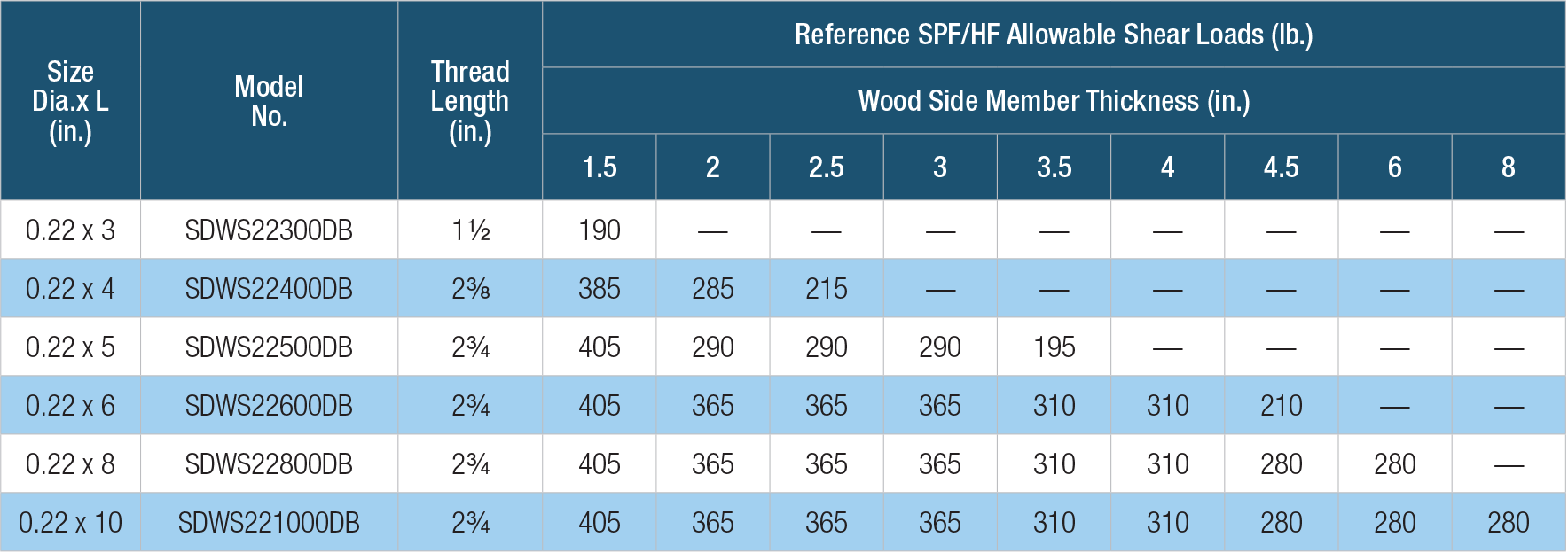

SDWS Timber Screw (Exterior Grade) — Allowable Shear Loads — Spruce-Pine-Fir and Hem-Fir Lumber

- All applications are based on full penetration into the main member. Full penetration is the screw length minus the side member thickness.

- Allowable loads are shown at the wood load duration factor of CD = 1.0. Loads may be increased for load duration per the building code up to a CD = 1.6. Tabulated values must be multiplied by all applicable adjustment factors per the NDS.

- Minimum fastener spacing requirements to achieve table loads: 6" end distance, 1 7/16" edge distance, 5/8" between staggered rows of fasteners, 4" between non-staggered rows of fasteners and 8" between fasteners in a row.

- For in-service moisture content greater than 19%, use CM = 0.7.

- Loads are based on installation into the side grain of the wood with the screw axis perpendicular to the face of the member.

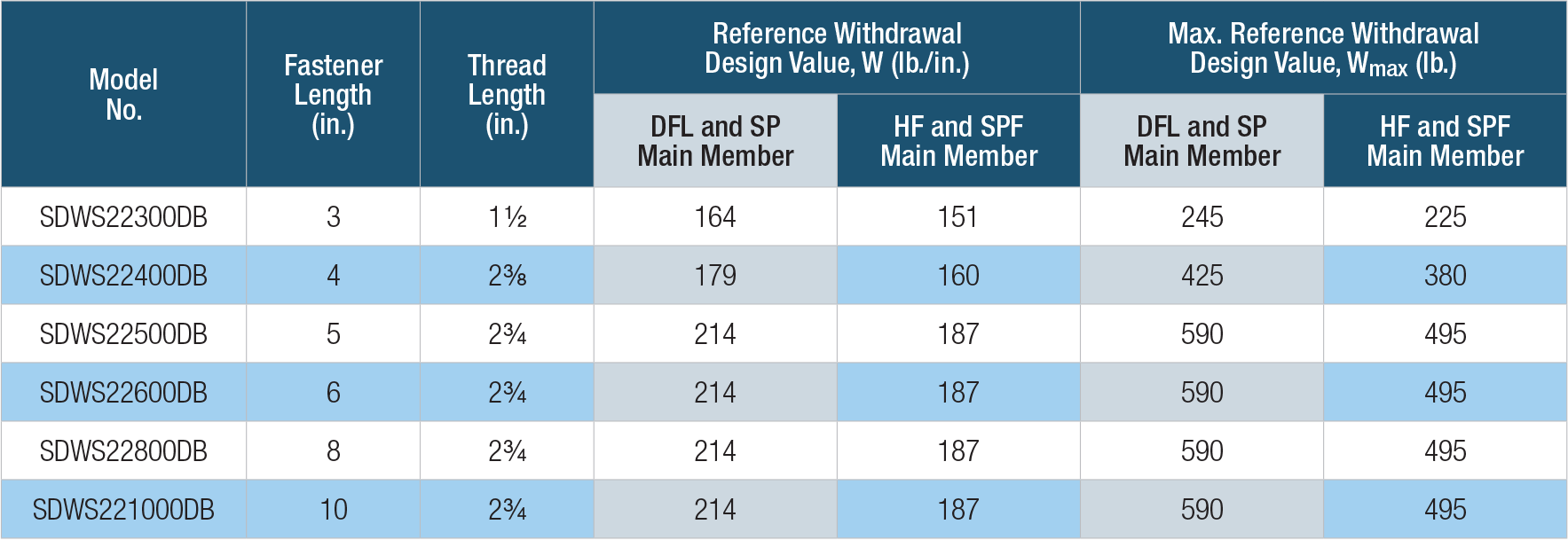

SDWS Timber Screw (Exterior Grade) — Allowable Withdrawal Loads — Douglas Fir–Larch, Southern Pine, Spruce-Pine-Fir and Hem-Fir Lumber

- The tabulated reference withdrawal design value, W, is in pounds per inch of the thread penetration into the side grain of the main member.

- The tabulated reference withdrawal design value, WMax, is in pounds where the entire thread length must penetrate into the side grain of the main member.

- Tabulated reference withdrawal design values, W and WMax, are shown at a CD = 1.0. Loads may be increased for load duration per the building code up to a CD = 1.6. Tabulated values must be multiplied by all applicable adjustment factors from the NDS as referenced in the IBC or IRC.

- Embedded thread length is that portion held in the main member including the screw tip.

- Values are based on the lesser of withdrawal from the main member or pull-through of a 1 1/2" side member.

- For in-service moisture content greater than 19%, use CM = 0.7.

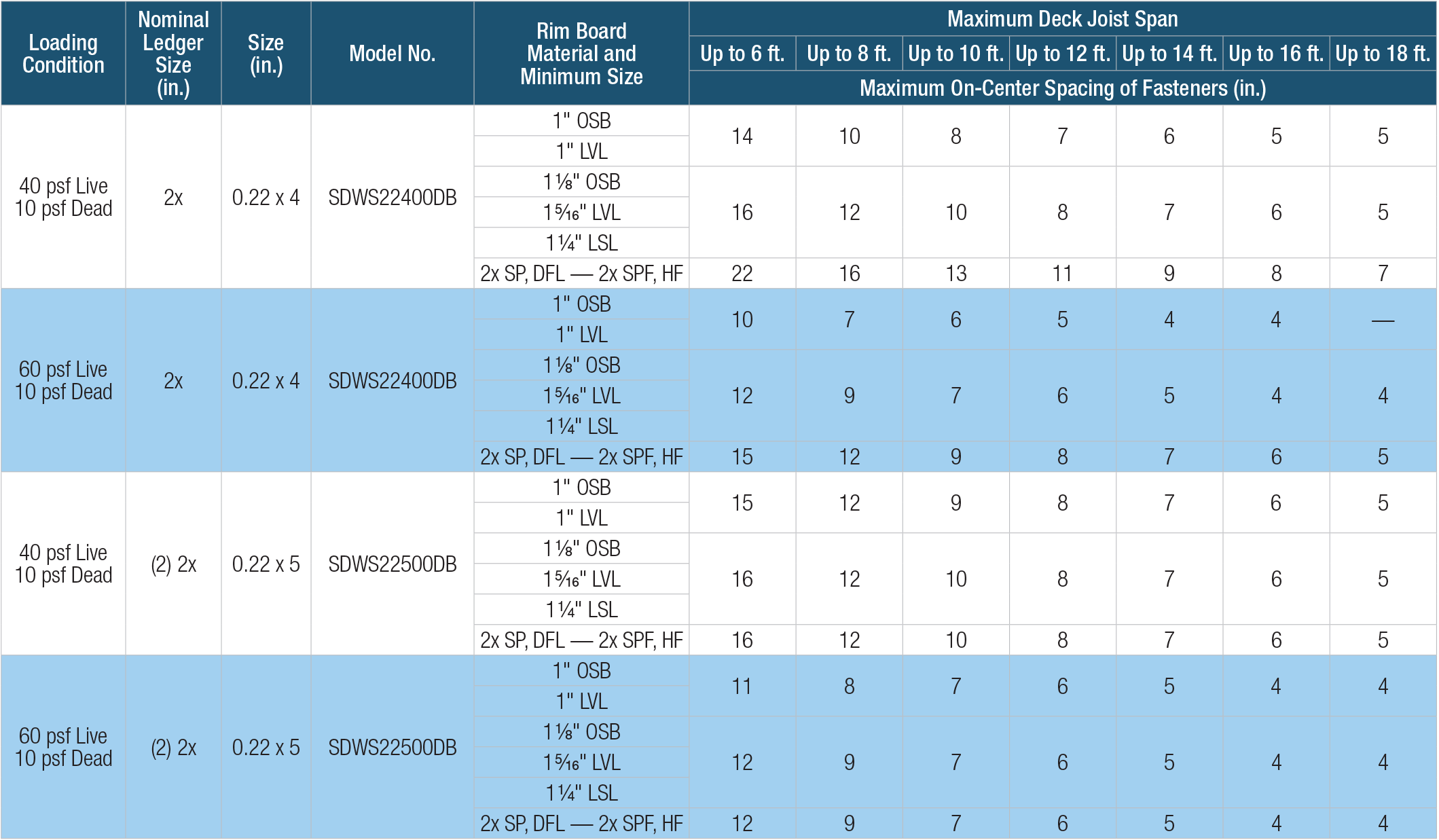

SDWS Timber Screw (Exterior Grade) — 2015 and 2018 IRC Compliant Spacing for a Sawn Lumber Deck Ledger-to-Rim Board

- SDWS screw spacing values are equivalent to 2018 IRC Table R507.9.1.3(1) and 2015 IRC Table R507.2. The table above also provides SDWS screw spacing for a wide range of materials commonly used for rim board, and an alternate loading condition as required by some jurisdictions.

- Sawn lumber rim board shall be spruce-pine-fir, hem-fir, Douglas fir–larch, or southern pine species. Ledger shall be hem-fir, Douglas fir–larch, or southern pine species.

- Fastener spacings are based on the lesser of single fastener ICC-ES AC233 testing of the Strong-Drive SDWS Timber screw with a safety factor of 5.0 or ICC-ES AC13 assembly testing with a factor of safety of 5.0. Spacing includes NDS wet service factor adjustment.

- Multiple ledger plies shall be fastened together per code independent of the SDWS screws.

- Rows of screws shall be vertically offset and evenly staggered. Screws shall be placed 1 1/2" to 2" from the top and bottom of the ledger or rim board with 3" minimum and 6" maximum between rows and spaced per the table. End screws shall be located 6" from the end and at 1 1/2" to 2" from the bottom of the ledger. For screws located at least 2" but less than 6" from the end, use 50% of the load per screw and 50% of the table spacing between the end screw and the adjacent screw, and for screws located between 2" and 4" from the end, predrill using a 5/32" drill.

- Structural sheathing between the ledger and rim board shall be a maximum of 1/2" thick and fastened per code.

- For ledger-to-rim attachment with 1/2" gap, see C-F-2019TECHSUP pp. 109–110.

See additional Load Tables, Technical Data and Installation Instructions for the Strong-Drive® SDWS Timber screw