Description

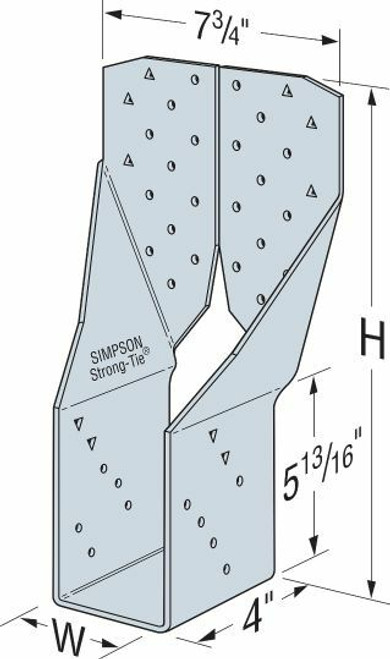

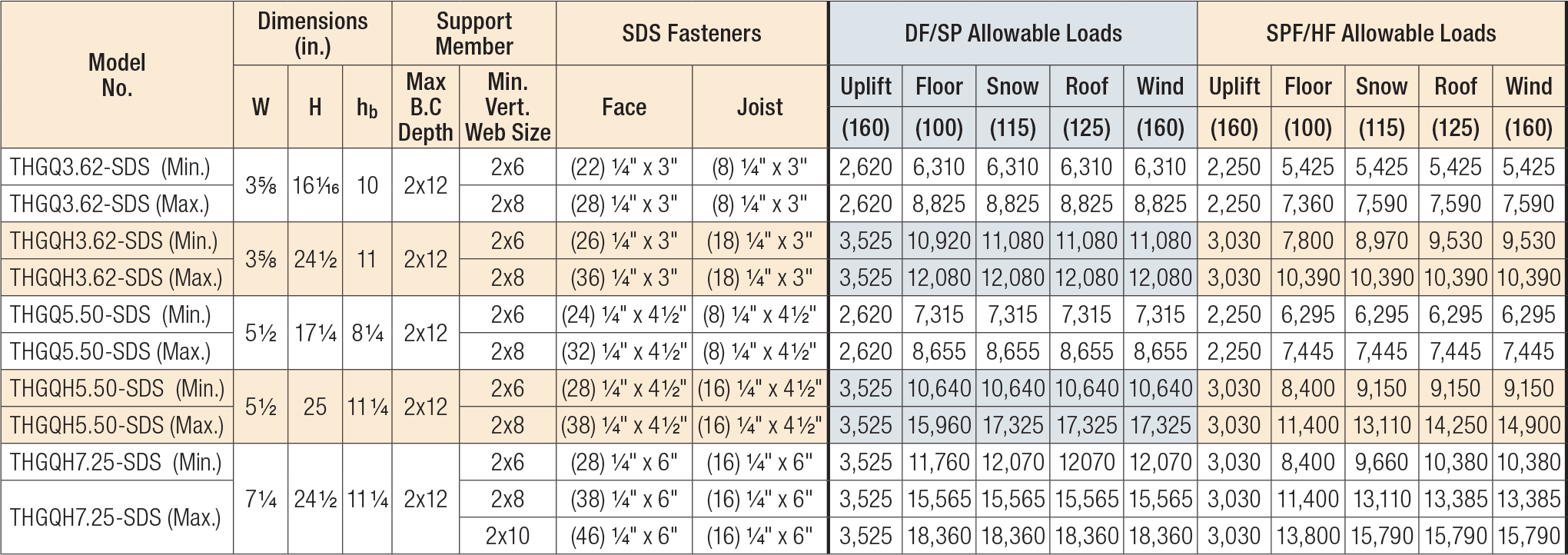

A lower-cost alternative to bolted hangers, the THGQ and THGQH hangers for multi-ply girder trusses use Strong-Drive® SDS Heavy-Duty Connector screws to provide high load capacities and easier installation compared to bolts. The Strong-Drive SDS Heavy-Duty Connector screws help transfer the load between the plies of the supporting girder when they penetrate all plies.

THGQ and THGQH models offer minimum and optional maximum fastener quantities to accommodate varying design needs. Allowable loads for various girder web member sizes provide additional installation options.

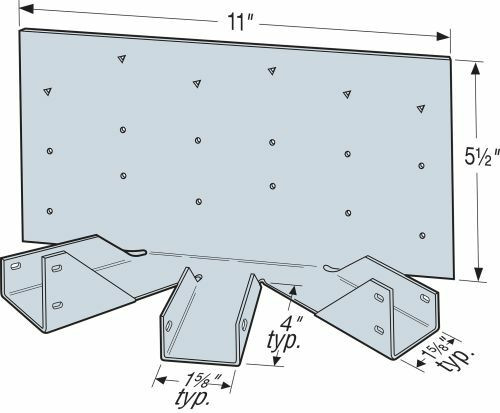

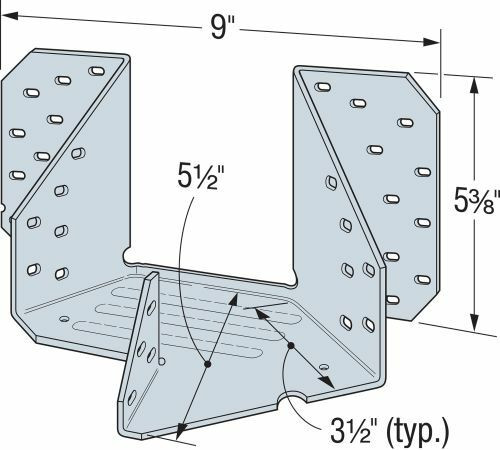

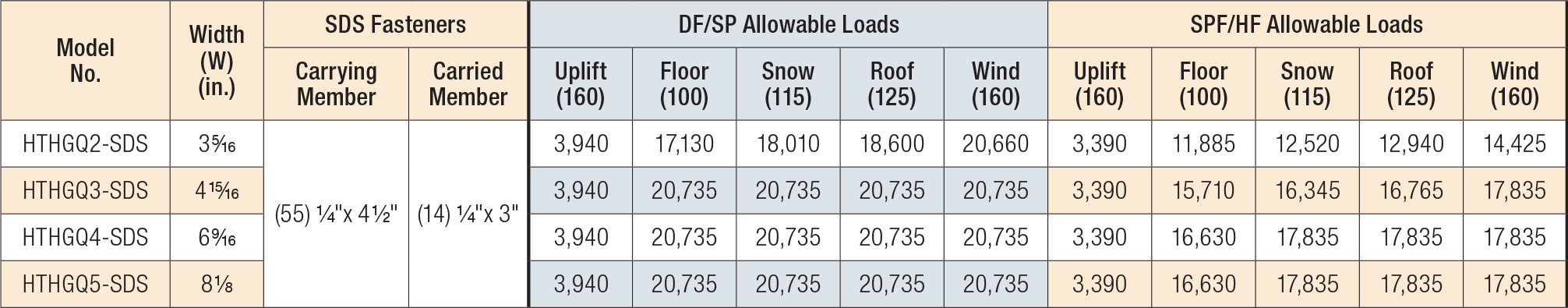

The HTHGQ is a high-load version designed to carry multi-ply trusses or composite lumber up to 5-ply girder trusses. For high load capacities and easier installation compared to bolts, the HTHGQ is designed for use with Strong-Drive SDS Heavy-Duty Connector screws.

Material

- THGQ — 7 gauge; THGQH/HTHGQ — 3 gauge

Finish

- THGQ — galvanized; THGQH/HTHGQ — Simpson Strong-Tie gray paint

Installation

- Use all specified fasteners; see General Notes.

- Can be installed filling round holes only, or filling round and triangle holes for maximum values.

- Strong-Drive SDS Heavy-Duty Connector screws supplied for all round and triangle holes. Installation may not require use of all Strong-Drive SDS Heavy-Duty Connector screws.

- All multiple members must be fastened together to act as a single unit.

- The thickness of the supporting girder must be equal to or greater than the screw length. For applications where the length of the supplied screws exceeds the thickness of the supporting girder, 3" or 4 1/2" screws may be substituted for the longer length screws with no load reduction, or a shim block may be used as approved by the Designer.

- Girders must be adequately laterally braced to prevent excessive displacement due to secondary torsional stresses (Ref ANSI/TPI 1-2014 Section 7.5.3.5).

Options

- See Hanger Options information.

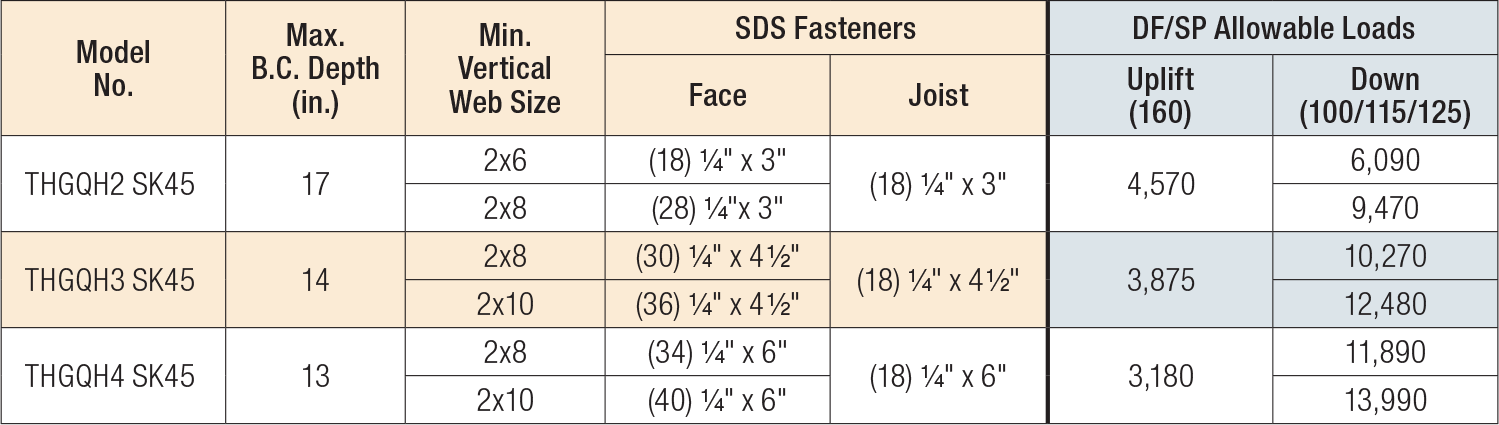

- THGQH may be skewed 45° for the models shown.

- For hem-fir or spruce-pine-fir members, multiply tabulated allowable loads for the skewed THGQH by 0.86. Connector must be installed centered on girder vertical webs.

Load Tables

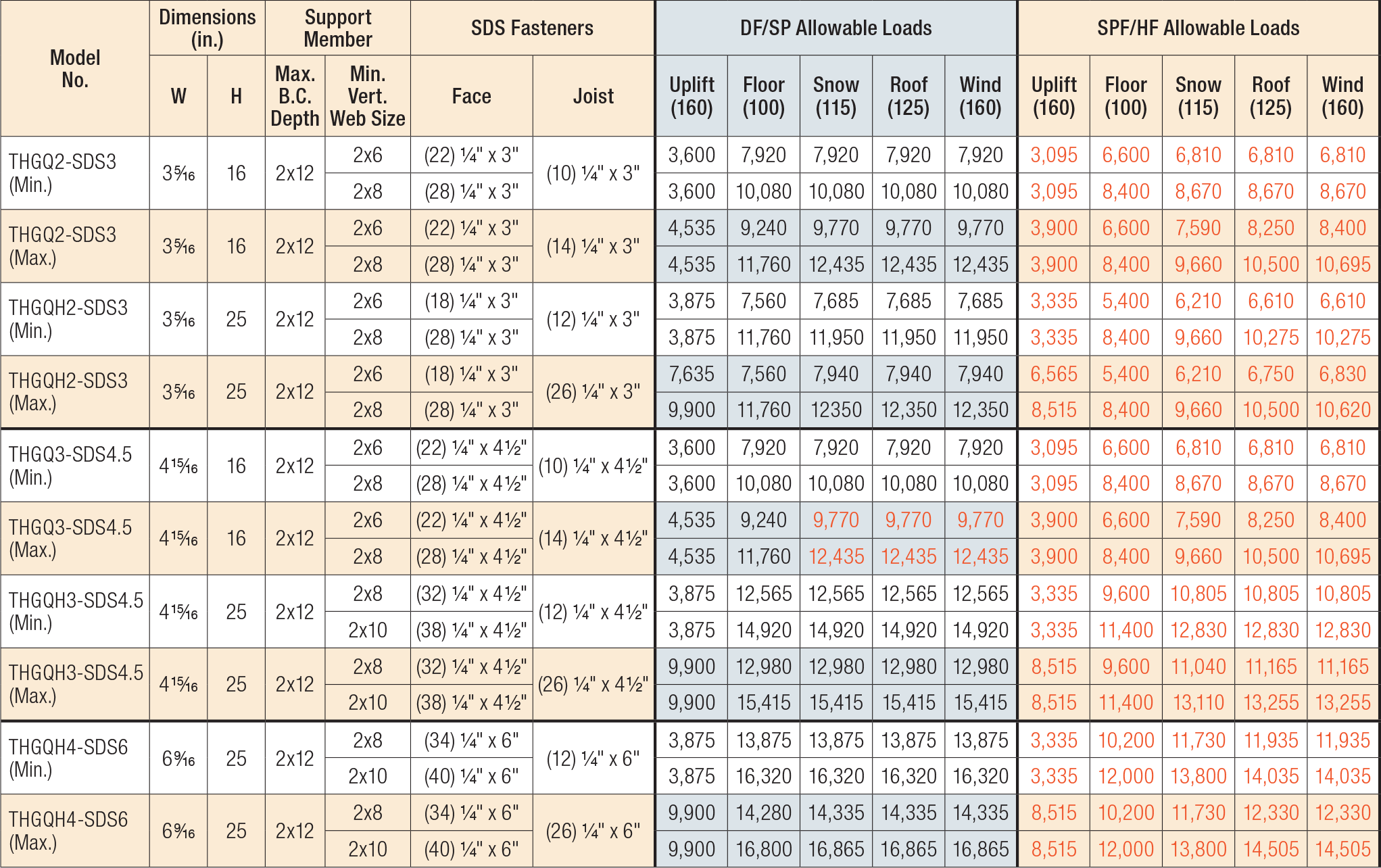

Allowable Loads for Multi-Ply Truss Girder

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Connector must be installed centered on girder vertical webs.

- Strong-Drive® SDS Heavy-Duty Connector screws may be installed through metal truss plates as approved by the Truss Designer, provided the requirements of ANSI/TPI 1-2014, Sections 7.5.3.4 and 8.9.2 are met (predrilling required through the plate using a 5/32" bit maximum).

- Strong-Drive® SDS Heavy-Duty Connector screws that penetrate all plies of the supporting girder (screws must penetrate a minimum of 1" into the last truss ply) may also be used to transfer the load through all the plies of the supporting girder. When SDS Heavy-Duty Connector screws do not penetrate all plies of the supporting girder truss, supplemental SDS screws at the hanger locations may be required to transfer the load to the truss plies not penetrated by the face fasteners, as determined by the Designer.

- The supporting girder truss must have adequate thickness to accommodate the screw length, so that the screw does not protrude out the back of the girder. 3"- or 4 1/2"-long Strong-Drive® SDS Heavy-Duty Connector screws may be substituted for longer SDS screws with no load reduction.

- For installations to LSL, use 1/4" x 3" Strong-Drive® SDS Heavy-Duty Connector screws and use the DF/SP table loads.

- Wind (160) is a download rating.

Allowable Loads for Heavy Multi-Ply Truss Girder

- Tabulated allowable loads must be selected based on duration of load as permitted by the applicable building code.

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Wind (160) is a download rating.

- Connector must be installed centered on a minimum 2x10 vertical web.

- A minimum three-ply carrying member is required for the tabulated loads.

- Carrying truss plies must be adequately fastened together as determined by the Designer.

- Truss chord cross-grain tension may limit allowable loads in accordance with ANSI/TPI 1-2014. Simpson Strong-Tie® Connector Selector® software includes the evaluation of cross-grain tension in its hanger allowable loads. For additional information, contact Simpson Strong-Tie.

- Strong-Drive® SDS Heavy-Duty Connector screws may be installed through metal truss plates as approved by the Truss Designer, provided the requirements of ANSI/TPI 1-2014, Sections 7.5.3.4 and 8.9.2 are met (predrilling required through the plate using a 5/32" bit maximum).

Allowable Loads for Structural Composite Lumber (SCL)

See THGQ footnotes above

- For Hem-Fir or Spruce-Pine-Fir members, multiply tabulated allowable loads for the skewed THGQH by 0.86. Connector must be installed centered on girder vertical webs