Description

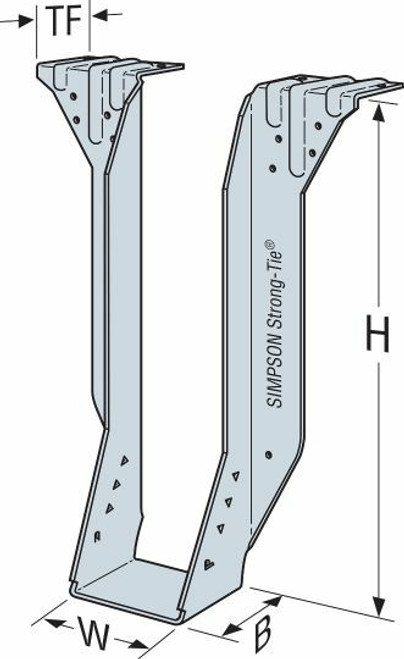

The BA hanger is a cost-effective hanger used for structural composite lumber and high-capacity I-joists. When used with I-joists, the positive-angle nailing at the joist seat allows the hanger to be used without web stiffeners.

The HB hanger is also available with higher capacity for structural composite lumber and heavier I-joist applications.

Material

- See top-flange hanger tables.

- For modified hangers, gauge may increase from that specified for non-modified hangers. Hanger configurations, height and fastener quantity may increase from the tables depending on joist size, skew and slope.

Finish

- BA and HB — Galvanized; BA and HB may be ordered hot-dip galvanized; specify HDG

Installation

- Use all specified fasteners; see General Notes and nailer table.

- BA and HB may be used for weld-on applications. The minimum size weld is a 2"-long fillet weld to each side of each top flange; weld size to match hanger material thickness. Distribute the weld equally on both top flanges. Welding cancels the top and face nailing requirements. Consult the code for special considerations when welding galvanized steel. The area should be well-ventilated; see General Instructions for the Installer, note k for weld information. Weld-on applications produce the maximum allowable download listed. For uplift loads refer to technical bulletin Top-Flange Hanger Reductions for Multiple-Ply Headers (T-C-WELDUPLFT).

- HB hanger requires the use of web stiffeners. BA min. nailing does not require web stiffeners. BA max. nailing requires the use of web stiffeners.

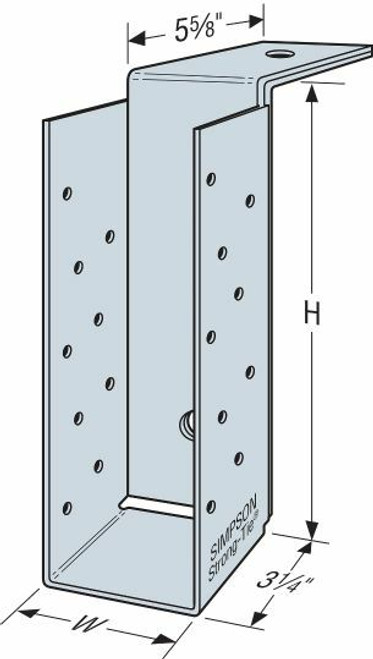

- Ledgers must be evaluated for each application separately. Check TF dimension, nail length and nail location on ledger.

- Refer to technical bulletin Sloped Joist in Non-Sloped Hangers (T-C-SLOPEJST) for information regarding load reductions on selected hangers which can be used without modification to support joists which have shallow slopes (≤ 3/4:12).

- Bevel cut the carried member for skewed applications.

Options

- Other widths are available; specify W dimension (the minimum W dimension is 1 9/16").

- The coating on special BA hangers will depend on the manufacturing process used. Check with your Simpson Strong-Tie representative for details. Hot-dip galvanized available: specify HDG.

- For modified hangers, fastener quantity may increase from the tables depending on joist size, skew and slope. All modified hangers are 12 ga.

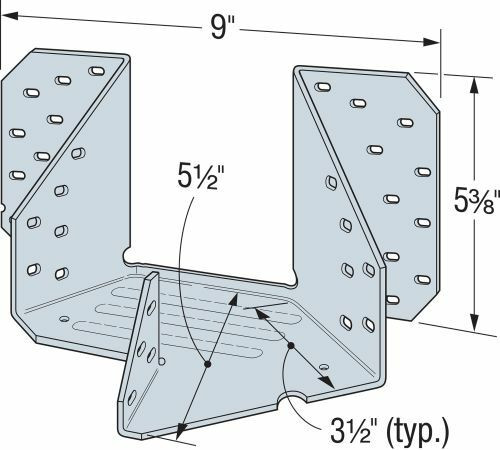

- The BA and HB hangers may be modified for slopes and/or skews up to 45º. The top flanges may be sloped up to 35º and may be open or closed up to 30º. See Modifications and Associated Load Reductions below.

Load Tables

See Hanger Options for hanger modifications, which may result in reduced loads.

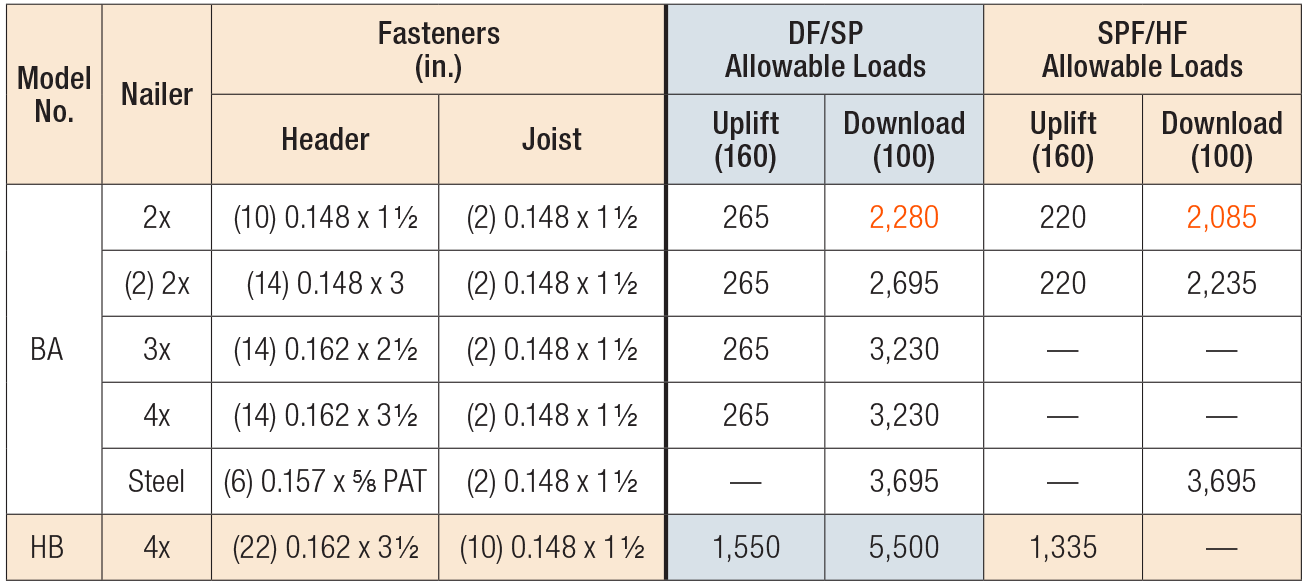

Nailer Table

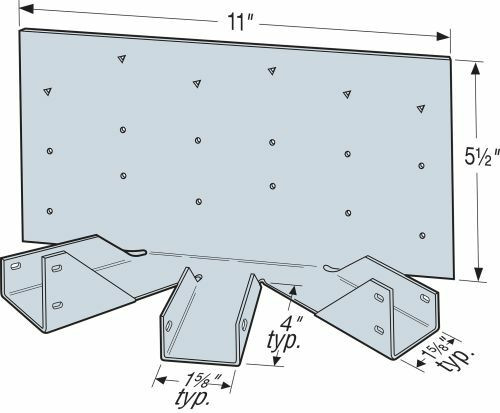

The table indicates the maximum allowable loads for BA and HB hangers used on wood nailers. Nailers are wood members attached to the top of a steel I-beam, concrete or masonry wall.

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern. BA hangers resist more uplift when web stiffeners are used. Refer to technical bulletin T-C-NAILUPLFT for additional information.

- Steel nailer allowable loads apply to steel header material with thickness between 1/4" and 3/4" with minimum Fy = 36 ksi. Design of steel header by Designer.

- 0.157"-diameter x 5/8"-long powder-actuated fastener = PDPAT-62KP. A red (level 5) or purple (level 6) load may be required to achieve specified penetration.

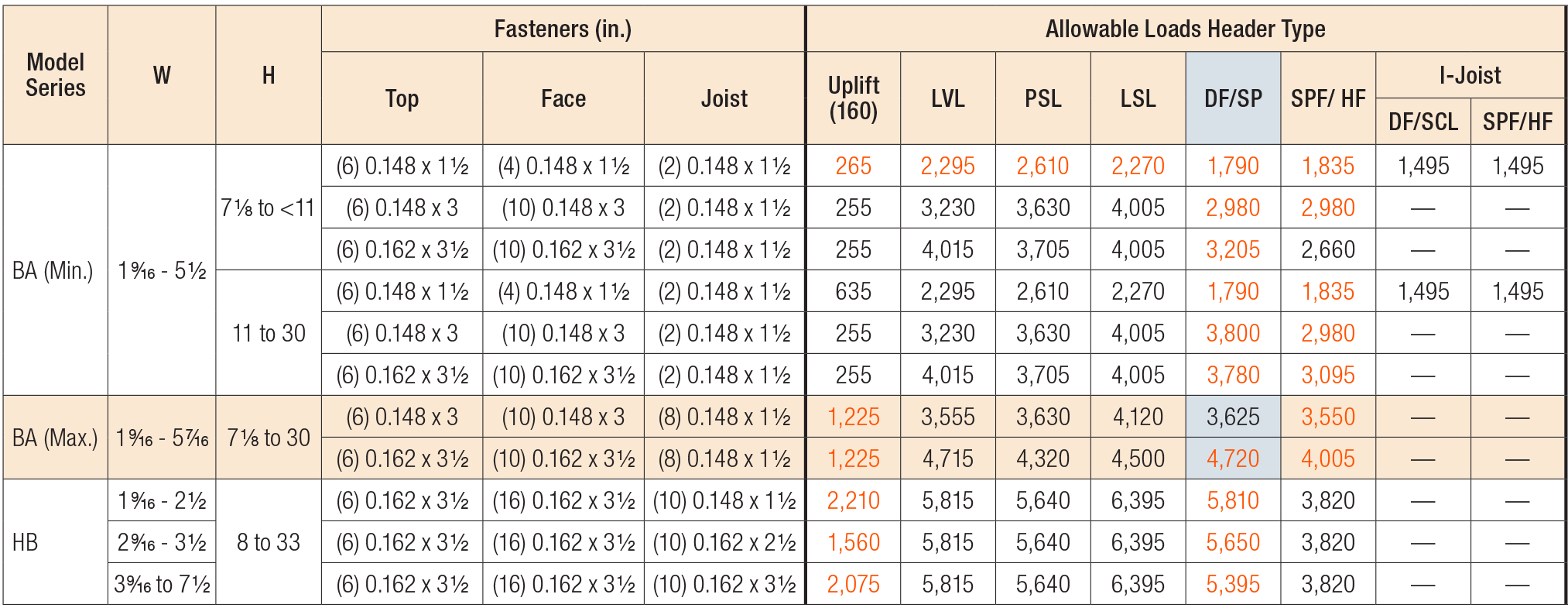

Various Header Applications

- This table assumes joists with Fc ⊥ = 750 psi. For other joists, check that bearing and joist nails are adequate.

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Uplift loads are based on DF/SP lumber. For SPF/HF, use 0.86 x DF/SP uplift load.

- Loads may not be increased for duration of load.

- SCL (structural composite lumber) is LVL (laminated veneer lumber), LSL (laminated strand lumber), and Parallam® PSL.

- LVL headers are assumed to be made primarily from Douglas fir or southern pine. For LVL made from spruce-pine-fir or similar less-dense veneers, use the values found in the SPF/HF column.

- DF I-joists headers include flanges made from solid sawn Douglas fir, LVL made primarily of DF/SP, or LSL. For I-joist header flanges with thicknesses from 1 5/16" to 1 3/8", use 0.85 of the I-joist header load. For I-joist header flanges with thicknesses from 1 1/8" to 1 1/4", use 0.75 of the I-joist header load.

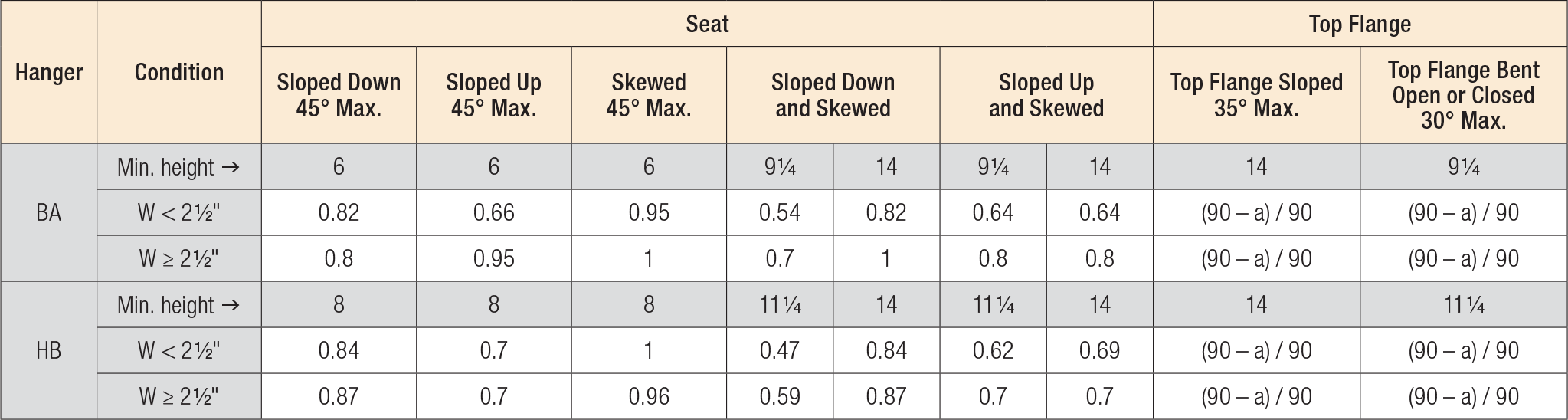

Modifications and Associated Load Reductions1

- Reduction factors are not cumulative. Use the lowest factors that apply.

- Web stiffeners are required for sloped or skewed conditions.

- For straight-line interpolation, "a" is the specified angle.

Reduction Factor Instructions

Allowable Download = Lower of (Seat or Top Flange) x (Table Load)

Allowable Uplift = 0.90 x (Table Load) for BA with W < 2 1/2"

= 0.71 x (Table Load) for HB with W < 2 1/2"

= 1.00 x (Table Load) for all others