Description

The SSTB anchor bolt is designed for maximum performance as an anchor bolt for holdowns and Simpson Strong-Tie®Strong-Wall® shearwalls. Extensive testing has been done to determine the design load capacity of the SSTB when installed in many common applications.

The Simpson Strong-Tie SSTB anchor bolts are code listed by ICC-ES under the 2012, 2015 and 2018 IBC® and IRC®.

Key Features

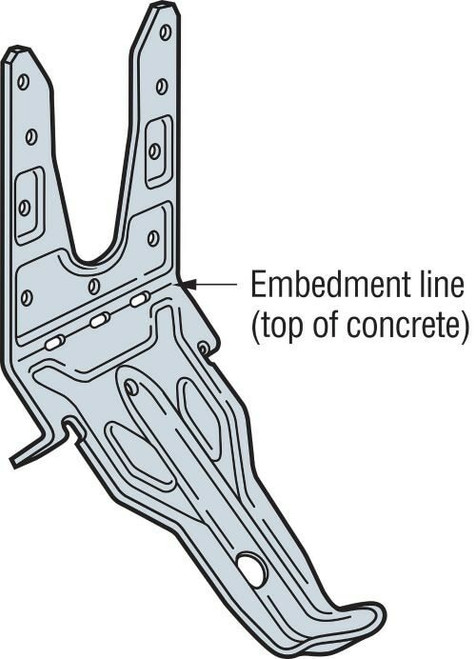

- Identification on the bolt head showing embedment angle and model

- Offset angle reduces side bursting, and provides more concrete cover

- Rolled thread for higher tensile capacity

- Stamped embedment line aids installation

- Available in HDG for additional corrosion resistance

Material

- ASTM F-1554, Grade 36

Finish

- None. May be ordered HDG; contact Simpson Strong-Tie.

Installation

- SSTB is suitable for monolithic and two-pour concrete applications.

- Nuts and washers for holdown attachment are not supplied with the SSTB; install standard nuts, couplers and/or washers as required.

- On HDG SSTB anchors, chase the threads to use standard nuts or couplers or use overtapped products in accordance with ASTM A563, for example Simpson Strong-Tie NUT5/8-OST, NUT7/8-OST, CNW5/8-OST, CNW7/8-OST.

- Install SSTB before the concrete pour using AnchorMate® anchor bolt holders. Install the SSTB per the plan view detail.

- Minimum concrete compressive strength is 2,500 psi.

- When rebar is required it does not need to be tied to the SSTB.

- Order SSTBL models (example: SSTB16L) for longer thread length (16L = 5 1/2", 20L = 6 1/2", 24L = 6", 28L = 6 1/2"). SSTB and SSTBL load values are the same. SSTB34 and SSTB36 feature 4 1/2" and 6 1/2" of thread respectively and are not available in "L" versions.

CMU

- One horizontal #4 rebar in the second course.

- One vertical #4 rebar in adjacent cell for 5/8"-diameter SSTB.

- One vertical #4 rebar in an adjacent cell and additional vertical #4 rebar(s) at 24" o.c. max. for 7/8"-diameter SSTBs (2 total vertical rebars for end wall corner, 3 total vertical rebars for midwall).

For two-pour (4" slab) installation loads:

- When using the SSTB20, use the equivalent loads of the SSTB16.

- When using the SSTB24, use the equivalent loads of the SSTB20.

- When using the SSTB34 or 36, use the equivalent loads of the SSTB28.

Load Tables

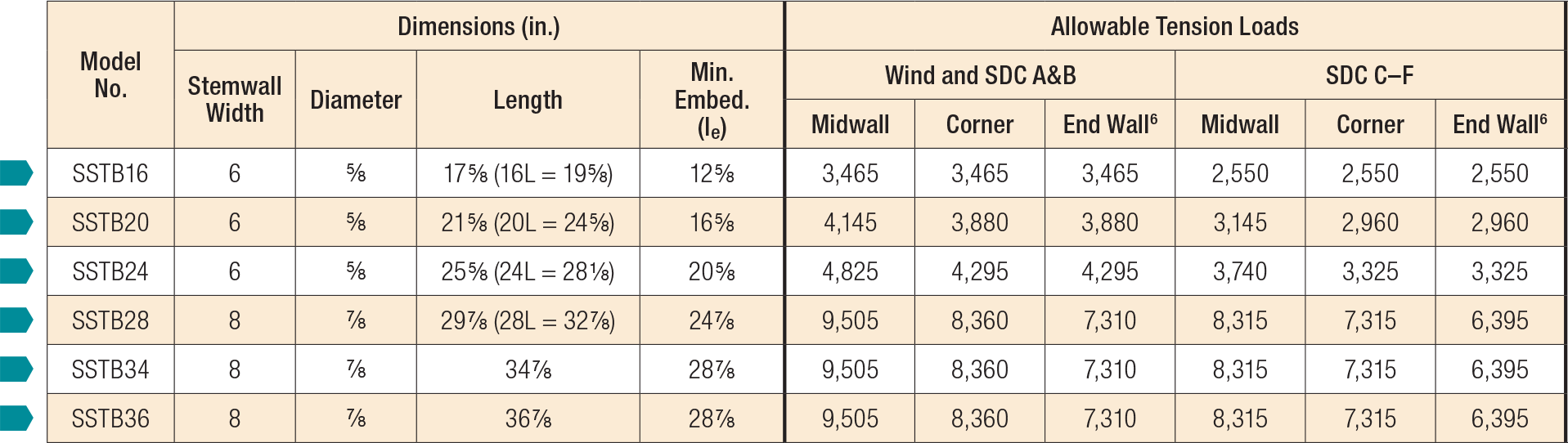

SSTB Bolts at Stemwall

These products are available with additional corrosion protection. Additional products on this page may also be available with this option, check with Simpson Strong-Tie for details.

- Rebar is required at the top of stem wall foundations, but is not required for slab-on-grade edge and garage curb, or stem wall garage front installations.

- Minimum end distances for SSTB bolts are as shown in graphics.

- To obtain LRFD values, multiply ASD seismic load values by 1.4 and wind load values by 1.67 (1.6 for 2012 IBC).

- Per Section 1613 of the IBC, detached one- and two-story dwellings in SDC C may use "Wind and SDC A&B" allowable loads.

- Midwall loads apply when anchor is 1.5 le or greater from the end. For bolts acting in tension simultaneously, the minimum bolt center-to-center spacing is 3 le.

- SSTB28, SSTB34 and SSTB36 with 3 7/8" end distance allowable loads are 6,330 lb. (Wind and SDC A&B) and 5,550 lb. (SDC C-F).

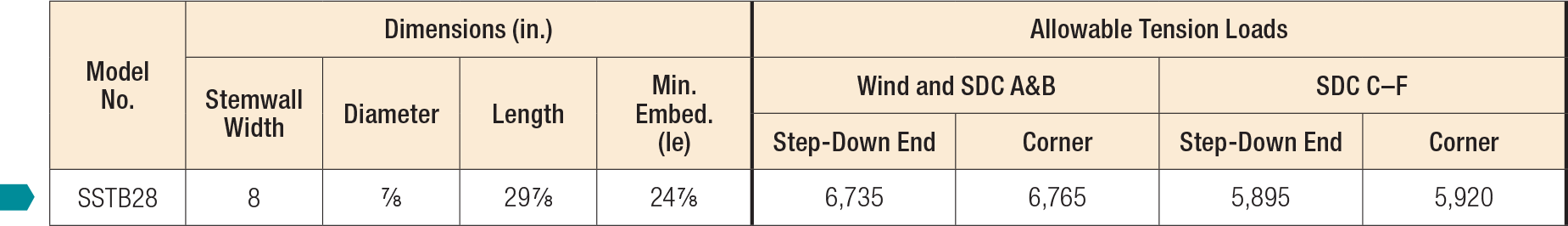

Stemwall Plan Views

These products are available with additional corrosion protection. Additional products on this page may also be available with this option, check with Simpson Strong-Tie for details.

- Rebar is required at the top of stem wall foundations, but is not required for slab-on-grade edge and garage curb, or stem wall garage front installations.

- Minimum end distances for SSTB bolts are as shown in graphics.

- To obtain LRFD values, multiply ASD seismic load values by 1.4 and wind load values by 1.67 (1.6 for 2012 IBC).

- Per Section 1613 of the IBC, detached one- and two-story dwellings in SDC C may use "Wind and SDC A&B" allowable loads.

- Midwall loads apply when anchor is 1.5 le or greater from the end. For bolts acting in tension simultaneously, the minimum bolt center-to-center spacing is 3 le.

These products are available with additional corrosion protection. Additional products on this page may also be available with this option, check with Simpson Strong-Tie for details.

- Rebar is required at the top of stem wall foundations, but is not required for slab-on-grade edge and garage curb, or stem wall garage front installations.

- Minimum end distances for SSTB bolts are as shown in graphics.

- To obtain LRFD values, multiply ASD seismic load values by 1.4 and wind load values by 1.67 (1.6 for 2012 IBC).

- Per Section 1613 of the IBC, detached one- and two-story dwellings in SDC C may use "Wind and SDC A&B" allowable loads.

- Midwall loads apply when anchor is 1.5 le or greater from the end. For bolts acting in tension simultaneously, the minimum bolt center-to-center spacing is 3 le.

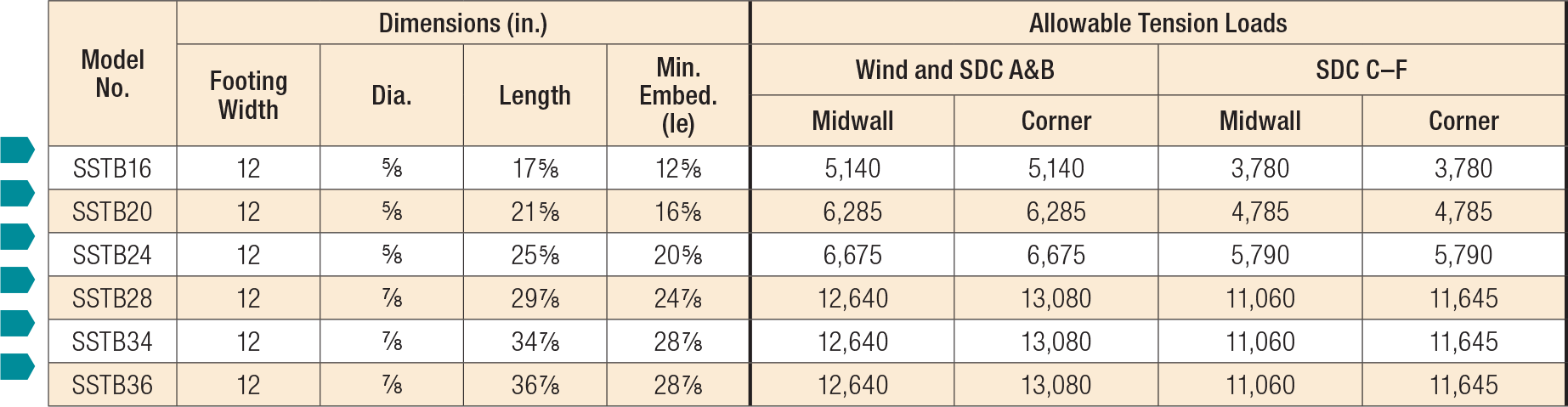

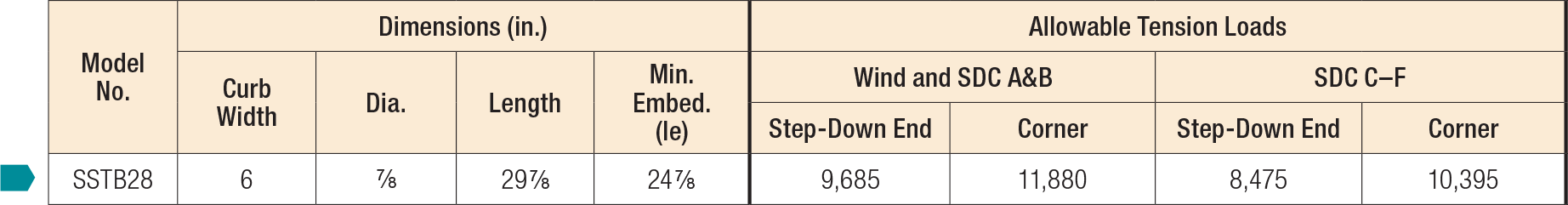

SSTB Bolts at Slab on Garage: Garage Curb

These products are available with additional corrosion protection. Additional products on this page may also be available with this option, check with Simpson Strong-Tie for details.

- Rebar is required at the top of stem wall foundations, but is not required for slab-on-grade edge and garage curb, or stem wall garage front installations.

- Minimum end distances for SSTB bolts are as shown in graphics.

- To obtain LRFD values, multiply ASD seismic load values by 1.4 and wind load values by 1.67 (1.6 for 2012 IBC).

- Per Section 1613 of the IBC, detached one- and two-story dwellings in SDC C may use "Wind and SDC A&B" allowable loads.

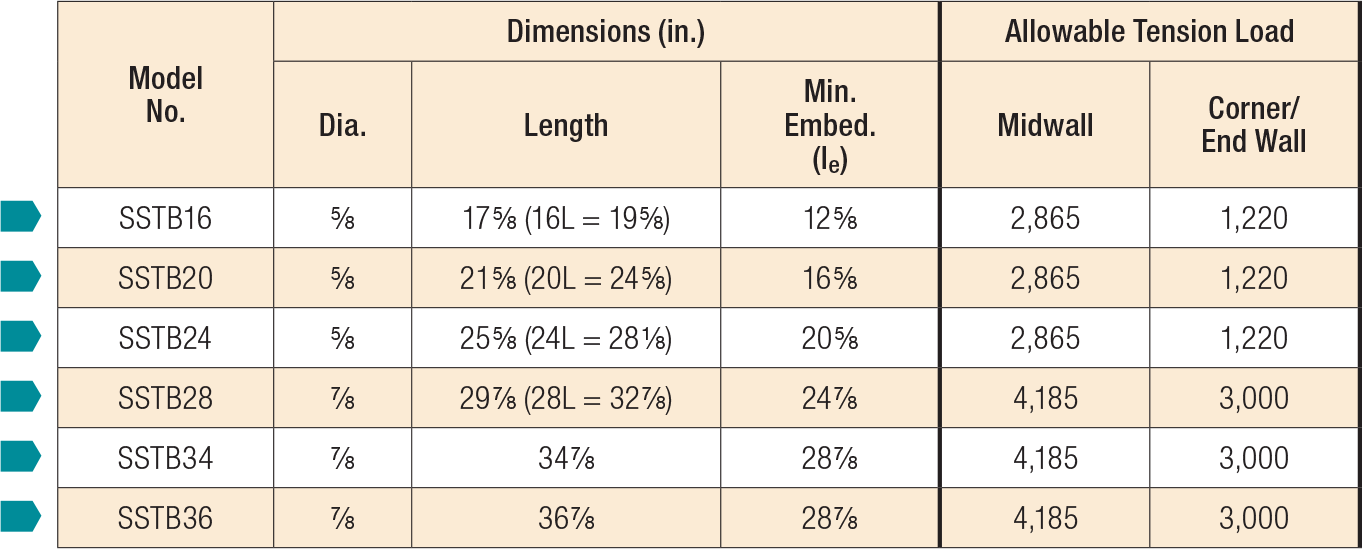

SSTB Bolts in 8" GFCMU

These products are available with additional corrosion protection. Additional products on this page may also be available with this option, check with Simpson Strong-Tie for details.

- Loads are based on a minimum CMU compressive strength, f'm, of 1,500 psi.

- Minimum end distance required to achieve midwall table loads is 1.5 le.

- Minimum end distance for corner/end wall loads is 4 1/4".

- Loads may not be increased for duration of load.

- Allowable loads are based on the average ultimate load with a safety factor of 5.0 per ACI 530.