Description

The Strong-DriveSD Connector screw is specifically designed to replace nails in certain Simpson Strong-Tieconnectors and is the only screw approved for that application. The load-rated SD screw has been tested and approved for use in many popular Simpson Strong-Tie products. In certain applications screws are easier and more convenient to install than nails, and the single-fastener load values achieved by the SD screw exceed those of typical 10d common or 16d common nails. In addition, the galvanized coating makes the SD screw ideal for interior and most exterior conditions.

Key Features

- Specifically designed to replace nails in certain Simpson Strong-Tie connectors and is the only screw approved for that application. The #9 and #10 SD screws replace 10d and 16d nails, respectively.

- The single-fastener load capacity of the #9 SD screw exceeds the capacity of a 10d common nail, while the single-fastener load capacity of the #10 SD screw exceeds that of the 16d common nail.

- Tested and approved for use in many of our most popular connectors for both interior and exterior applications.

- Ideal for use in connector applications where more control is desired or using a hammer is inconvenient.

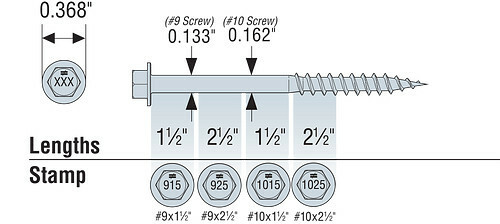

- 1/4" hex head with 0.37"-dia. integrated washer is stamped with the Simpson Strong-Tie "≠" sign and the fastener size for easy identification after installation.

- Shank is specifically designed to match the fastener holes in Simpson Strong-Tie connectors.

- Optimized heat treating for ductility and strength.

- Hex driver included.

Mechanically galvanized coating meets ASTM B695 Class 55, is recommended for use with certain preservative-treated woods and recognized as an alternate to hot-dip galvanized in ESR-3046; it is compliant with the 2012 International Residential Code®.

Applications

- Simpson Strong‑Tie connectors

Load Tables

Links to load tables for connectors installed with the Strong-Drive® SD Connector Screw can be found here: Connectors Approved for Use with the Strong-Drive® SD Connector screw.

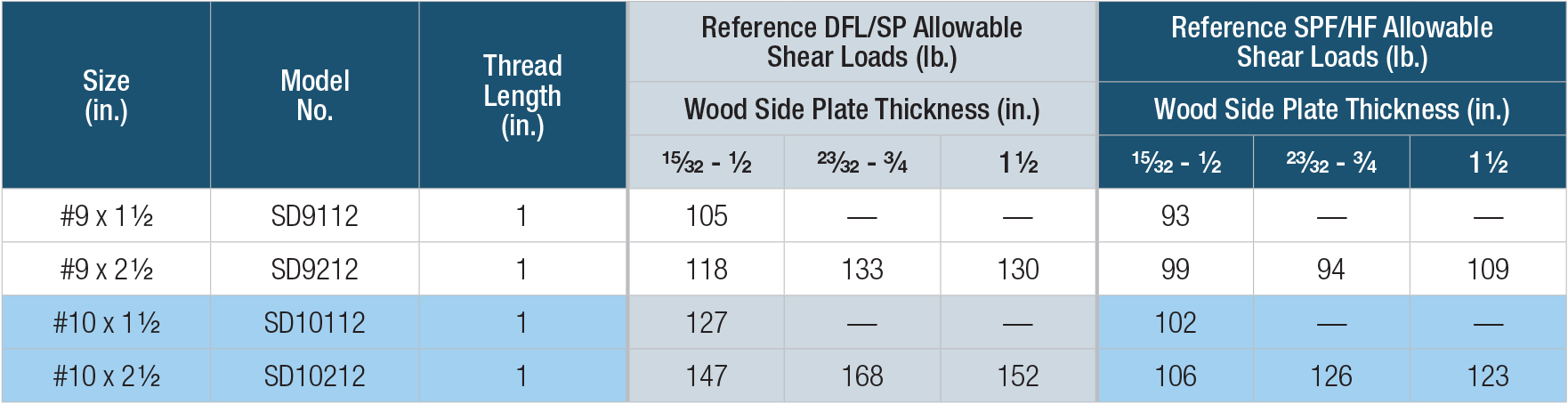

SD — Allowable Shear Loads for Wood Connections

- Allowable loads are shown at the wood load duration factor of CD = 1.00. Loads may be increased for load duration per the building code up to a CD = 1.60.

- The 15/32" and 23/32" side members must be plywood or OSB with minimum equivalent specific gravities of 0.50 for DFL and SP design values, and 0.42 for SPF and HF design values. See NDS, Table 12.3.3B for specific WSP grades and associated equivalent specific gravities.

- Loads are based on connections with main members of DFL/SP or SPF/HF and side members as shown and described in table note 2. Screws shall be installed normal to the surface of the wood members.

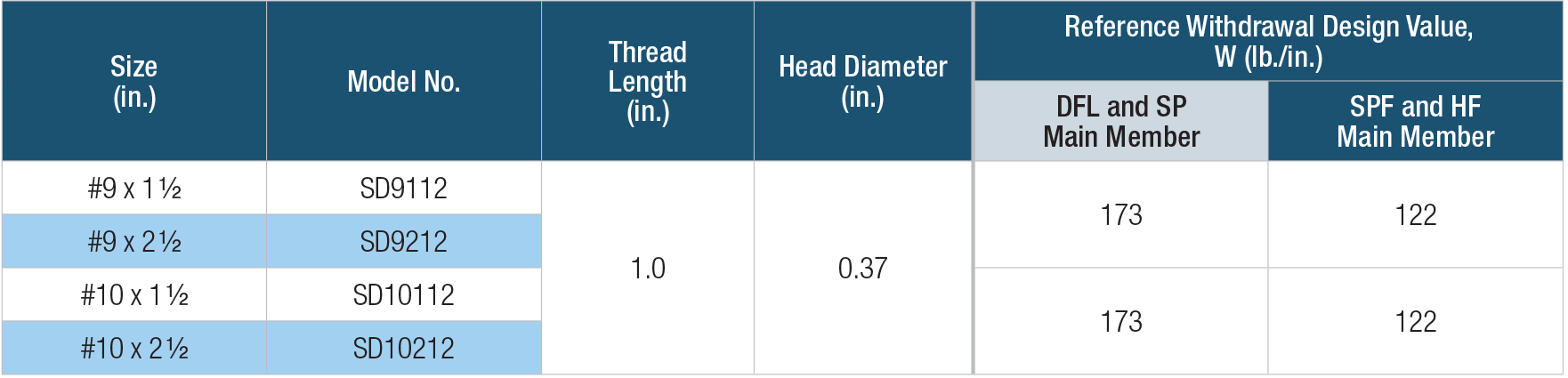

SD — Allowable Withdrawal Loads— DFL, SP, SPF, HF Lumber

- The tabulated reference withdrawal design value, W, is in pounds per inch of the thread penetration into the side grain of the main member.

- Tabulated reference withdrawal design value, W, must be multiplied by all applicable adjustment factors from the NDS as referenced in the IBC or IRC.

- Embedded thread length is that portion held in the main member including the screw tip.

- For connections with 15/32" thick plywood or OSB side members, reference withdrawal design values, W, must be limited by the head pull-through design value of 130 lb.

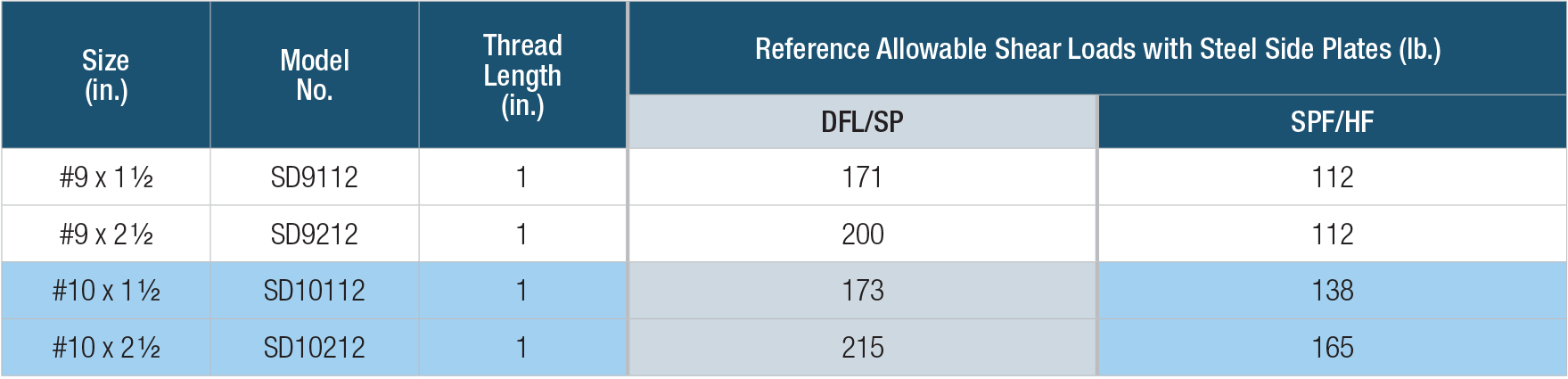

SD — Allowable Shear Loads — Steel Side Plate

- Loads are given for CD = 1.00 and may be increased for load duration per the building code to CD = 1.60.

- Steel side-plate thickness is 33 to 100 mil (20 – 12 ga.).