Description

The Strong-Drive SDWS Timber (Interior Grade) screw – formerly, the SDWS Log screw – is a structural wood screw available in a variety of lengths and is designed for cross-laminated timber assemblies, mass timber construction, log-home construction, ledgers and general interior applications. These 0.195"- and 0.220"-diameter structural fasteners require less torque to install than comparable fasteners, and the large-diameter washer head pulls members down easily, eliminating the need to use extra washers. It is code listed under IAPMO-UES ER-192 and meets 2015 and 2018 IRC® and IBC® code requirements for several common wood framing applications.

Key Features

- SawTooth™ point ensures fast starts, reduces installation torque and eliminates the need for predrilling in most applications

- Serrated thread reduces splitting and damage

- Large, low-profile .075"-diameter washer head with nibs provides maximum bearing area and makes countersinking easy

- 6-lobe, T40 drive provides positive engagement that makes the screw easy to drive and improves bit life (replacement driver bit: BIT40T-134)

- Size identification on all Simpson Strong-Tie screws

- US Patent: 9,523,383

Applications

- Surface splines, lap joints, timber framing, ledgers, log-home construction and general interior applications

- Testing in a variety of mass timber applications is underway

Product Includes

- Replacement driver bit: BIT40T-134

Warning

- Industry studies show that hardened fasteners can experience performance problems in wet and corrosive environments. Accordingly, use this product in dry, interior and noncorrosive environments only.

Load Tables

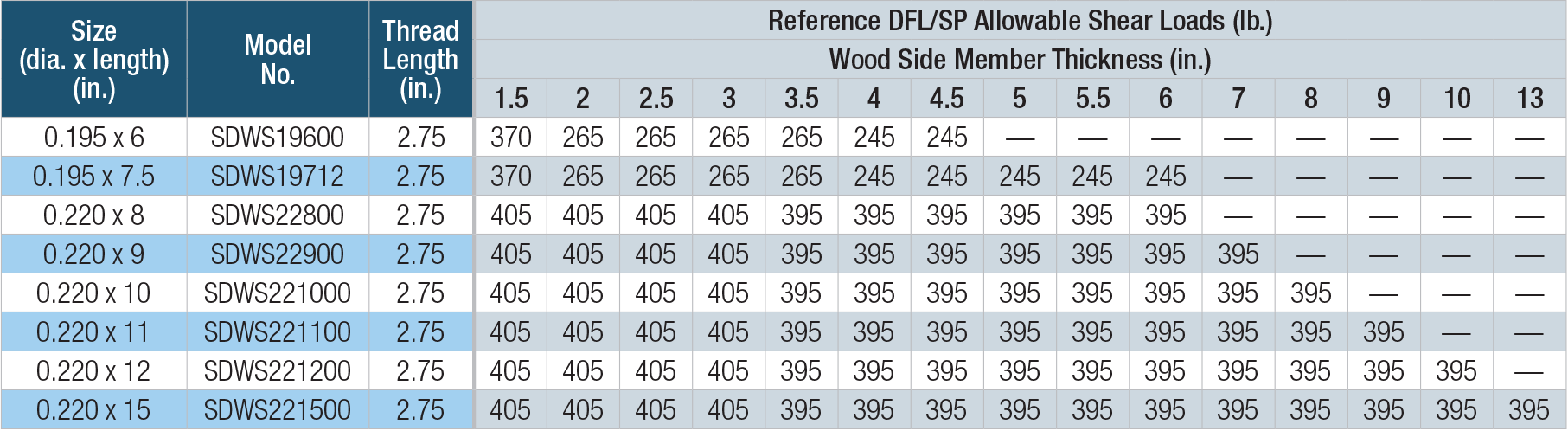

SDWS Timber (Interior Grade) — Allowable Shear Loads — Douglas Fir–Larch and Southern Pine

SDWS Timber (Interior Grade) — Allowable Shear Loads — Spruce-Pine-Fir and Hem-Fir

- Design values are based on full fastener embedment and the adjacent members are in contact with each other.

- Allowable loads are shown at the wood load duration factor of CD = 1.0. Loads may be increased for load duration up to a CD = 1.6.

- Tabulated values must be multiplied by all applicable adjustment factors per the NDS.

- Minimum fastener spacing requirements: 6" end distance, 1 7/16" edge distance, 5/8" between staggered rows of fasteners, 4" between non-staggered rows of fasteners and 8" between fasteners in a row.

- Loads are for in-service moisture content less than or equal to 19% (CM=1.0).

- Loads are based on installation into the side grain of the wood member with the screw axis perpendicular to the face of the wood member.

SDWS Timber (Interior Grade) — Allowable Withdrawal Loads — Douglas Fir–Larch, Southern Pine, Spruce-Pine-Fir and Hem-Fir Lumber

- The tabulated reference withdrawal design value, W, is in pounds per inch of the thread penetration into the side grain of the main member.

- The tabulated reference withdrawal design value, Wmax, is in pounds where the entire thread must penetrate into the side grain of the main member.

- Tabulated reference withdrawal design values (CD=1.0), W and Wmax, must be multiplied by all applicable adjustment factors from the NDS as referenced in the IBC or IRC.

- Embedded thread length is that portion held in the main member including the screw point.

- Values are based on the lesser of withdrawal from the main member or pull-through of a 1.5" side member.

- Loads are for in-service moisture content less than or equal to 19% (CM=1.0).

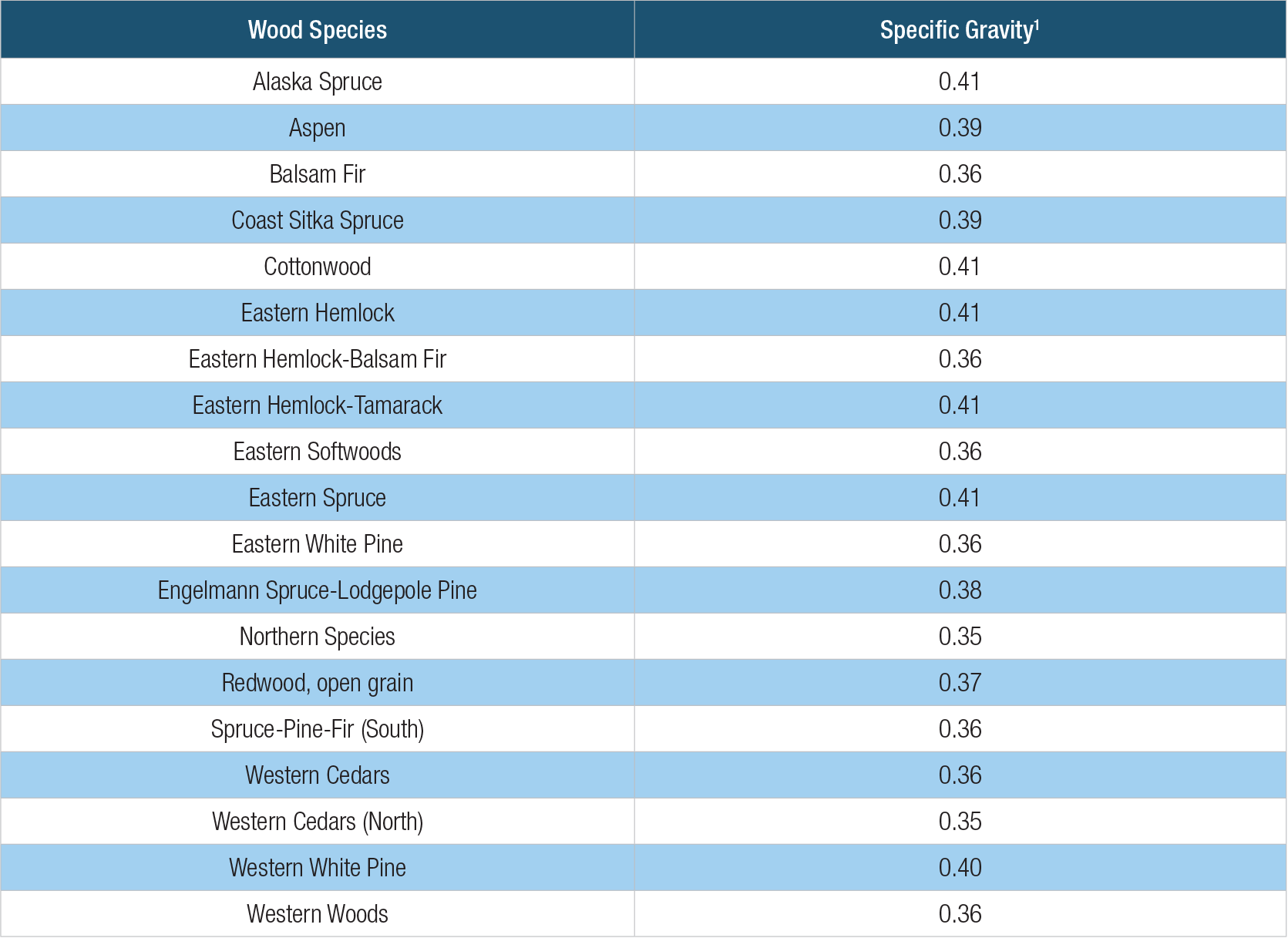

Wood Species Combinations in the Specific Gravity Range 0.35 to 0.41

Allowable Loads for Strong-Drive SDWS Timber Screws (Interior Grade) with Expanded Specific Gravity Options

Allowable load tables on the following pages provide shear and withdrawal capacities for wood species with an assigned specific gravity of 0.35 to 0.41. Wood species with a specific gravity within this range are provided below.

- Specific gravity as assigned in NDS-18 Table 12.3.3A.

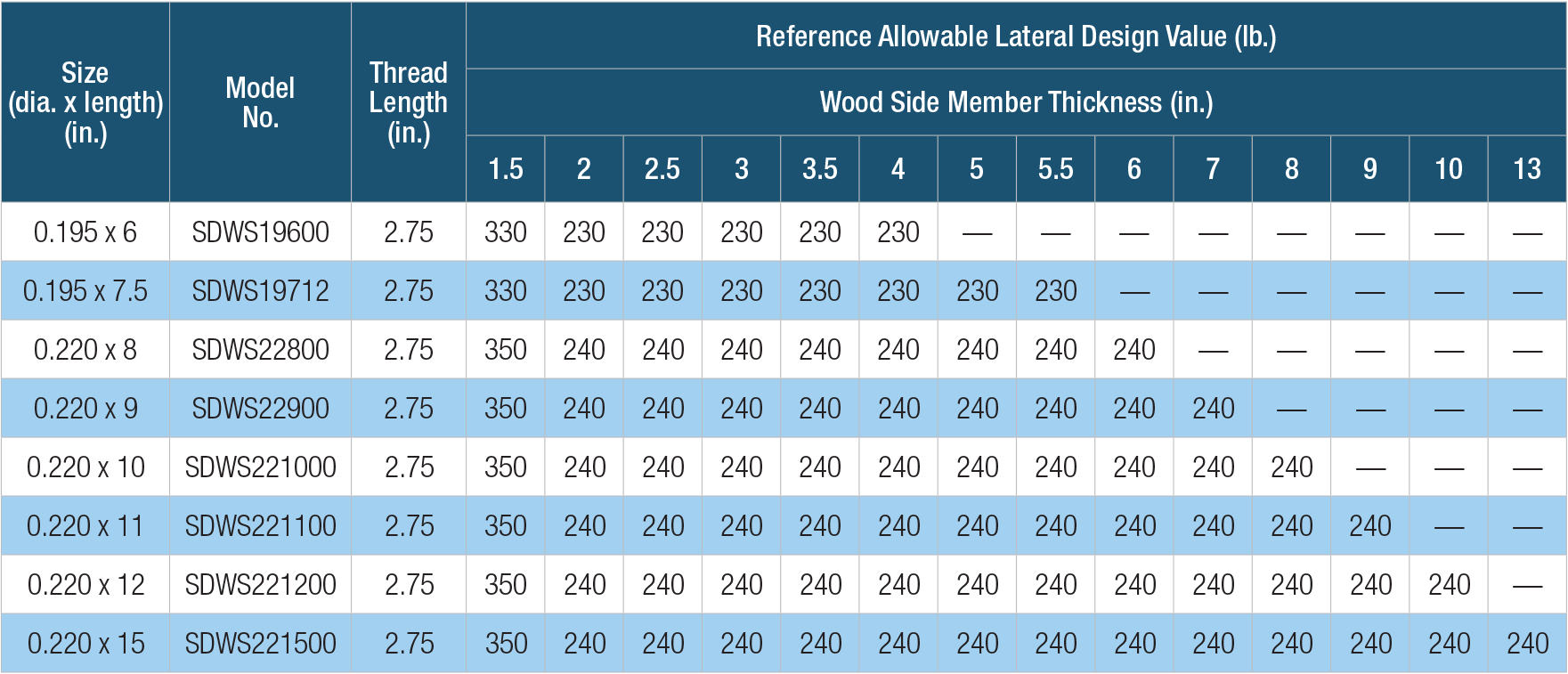

SDWS Timber (Interior Grade) — Allowable Lateral Loads in the Specific Gravity Range 0.35 to 0.41

- Design values are based on full fastener embedment and the adjacent members are in contact with each other.

- Allowable loads are shown at the wood load duration factor of CD = 1.0. Loads may be increased for load duration per the building code up to a CD = 1.6. Tabulated values must be multiplied by all applicable adjustment factors per the NDS.

- Minimum fastener spacing requirements: 6" end distance, 1 7/16" edge distance, 5/8" between staggered rows of fasteners, 4" between non-staggered rows of fasteners and 8" between fasteners in a row.

- For in-service moisture content less than or equal to 19% (CM=1.0).

- The load tables are based on testing in accordance with ICC-ES AC233, with an applied factor of safety of 5.0.

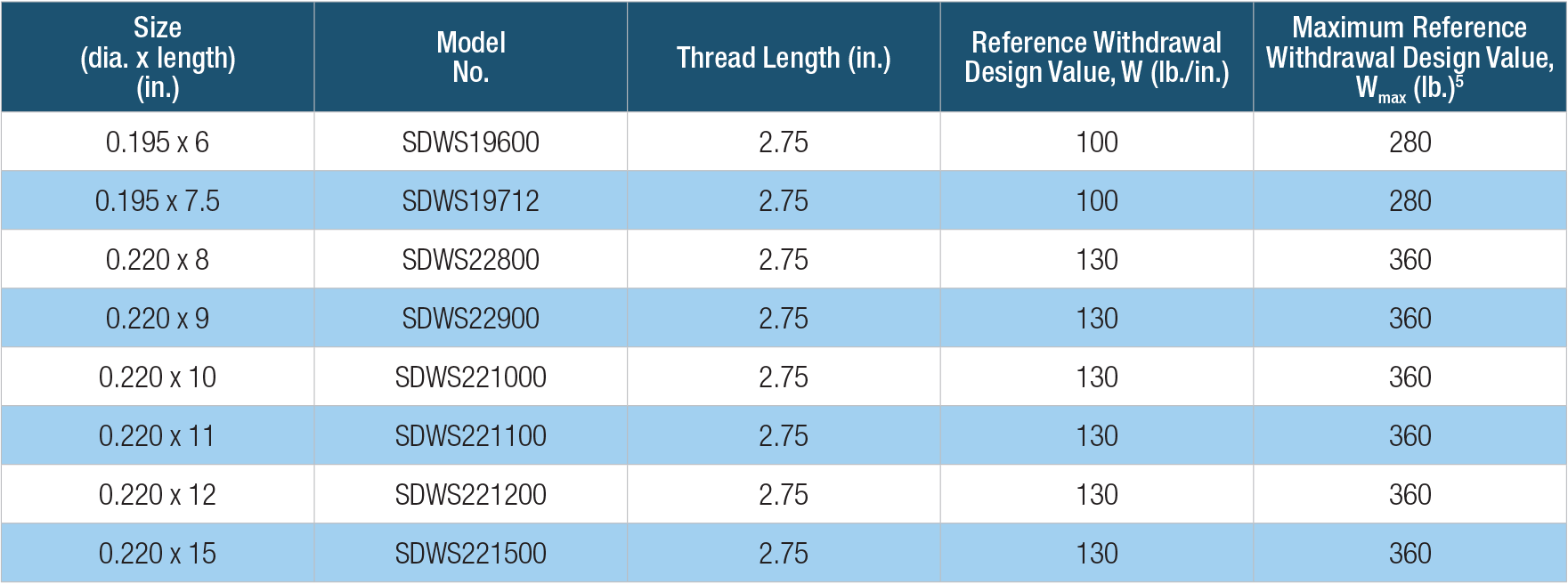

SDWS Timber (Interior Grade) — Allowable Withdrawal Loads in the Specific Gravity Range 0.35 to 0.41

- The tabulated reference withdrawal design value, W, is in pounds per inch of the thread penetration into the side grain of the main member.

- The tabulated reference withdrawal design value, Wmax, is in pounds where the entire thread must penetrate into the side grain of the main member.

- Tabulated reference withdrawal design values, W and Wmax, are shown at the wood load duration factor of CD = 1.0. Loads may be increased for load duration per the building code up to a CD = 1.6. Tabulated values must be multiplied by all applicable adjustment factors per the NDS as referenced in the IBC or IRC.

- Embedded thread length is that portion held in the main member including the screw point.

- Values are based on the lesser of withdrawal from the main member or pull-through of a 1.5" side member.

- For in-service moisture content less than or equal to 19% (CM=1.0).

- The load tables are based on testing in accordance with ICC-ES AC233, with an applied factor of safety of 5.0.