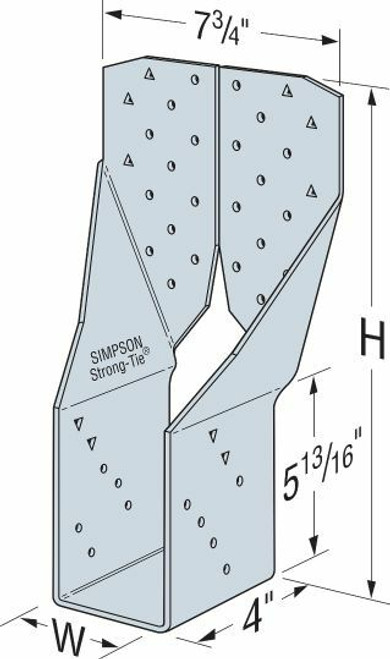

Description

The THA series have extra long straps that can be field-formed to give height adjustability and top-flange hanger convenience. THA hangers can be installed as top-flange or face-mount hangers.

THA4x and THA2x-2 models feature a dense nail pattern in the straps, which provides more installation options and allows for easy top-flange installation.

Material

- See table

Finish

- Galvanized. Some products available in ZMAX® coating. See Corrosion Information.

Installation

- Use all specified fasteners; see General Notes.

The following installation methods may be used:

- Top-Flange Installation — the straps must be field-formed over the header — see table for minimum top-flange requirements. Install top and face nails according to the table. Top nails shall not be within 1/4" from the edge of the top-flange members. For the THA29, nails used for joist attachment must be driven at an angle so that they penetrate through the corner of the joist and into the header. For all other top-flange installations, straighten the double-shear nailing tabs and install the nails straight into the joist.

- Face-Mount (Min.) Installation — install face nails according to the table, with at least half of the required fasteners in the top half of the header. Not all nail holes in the straps will be filled. Nails must have a minimum 1/2" edge distance. Straighten the double-shear nailing tabs and install the joist nails straight into the joist. The face-mount (min.) installation option accommodates conditions where the supported member hangs either partially or entirely below the header.

- Face-Mount (Max.) Installation — install face nails according to the table. Not all nail holes in the straps will be filled except for the following models: THA29, THA213, THA218 and THA413. For all other models with more nail holes than required, the straps may be installed straight or wrapped over the header, with the tabulated quantity of face nails installed into the face and top of the header. The lowest four face holes must be filled. Nails used for the joist attachment must be driven at an angle so that they penetrate through the corner of the joist into the header.

- Uplift — lowest face nails must be filled to achieve uplift loads.

Options

- THA hangers available with the header flanges turned in for 3 5/8" (except THA413) and larger, with no load reduction — order THAC hanger.

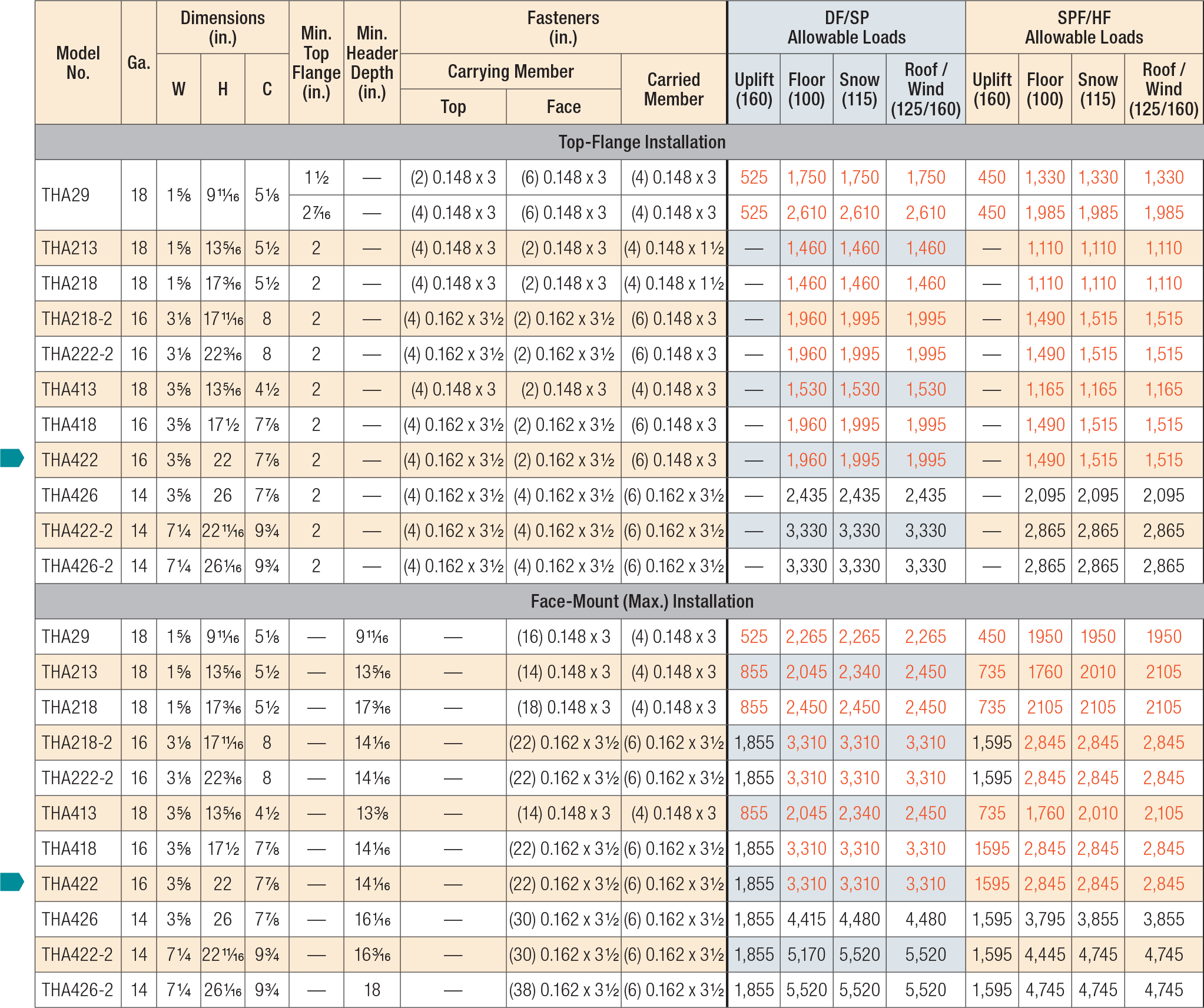

Load Tables

These products are available with additional corrosion protection. Additional products on this page may also be available with this option, check with Simpson Strong-Tie for details.

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Wind (160) is a download rating.

- Min. top flange refers to the minimum length of strap that must be field-formed over the header. The tabulated loads for the THA29 with 1 1/2" min. top flange are based on a single 2x carrying member; all other top-flange installation loads are based on a minimum 2-ply 2x carrying member. For 4x2 truss carrying members with double top chords, use the specified fasteners for full tabulated values. For single 4x2 top chord or nailer applications, refer to the Nailer Table.

- Face-mount installation loads are based on a two-ply 2x carrying member minimum. For single 2x carrying members, use 0.148" x 1 1/2" nails in the carrying member and tabulated fasteners in the carried member, and use 0.80 of the table value for 18 gauge, and 0.68 of the table value for 16 gauge and 14 gauge.

- For the THA 2x models, one strap may be installed vertically according to the face-mount nailing requirements and the other strap wrapped over the truss chord according to the top-flange nailing requirements (see illustration) and achieve full tabulated top-flange installation loads.

- Refer to installation instructions regarding fastener installation into carried (joist) member. Based on the installation condition, nails will be installed either straight with straighted double-shear nailing tabs or slanted.

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

Typical THA29 Top Flange Installation

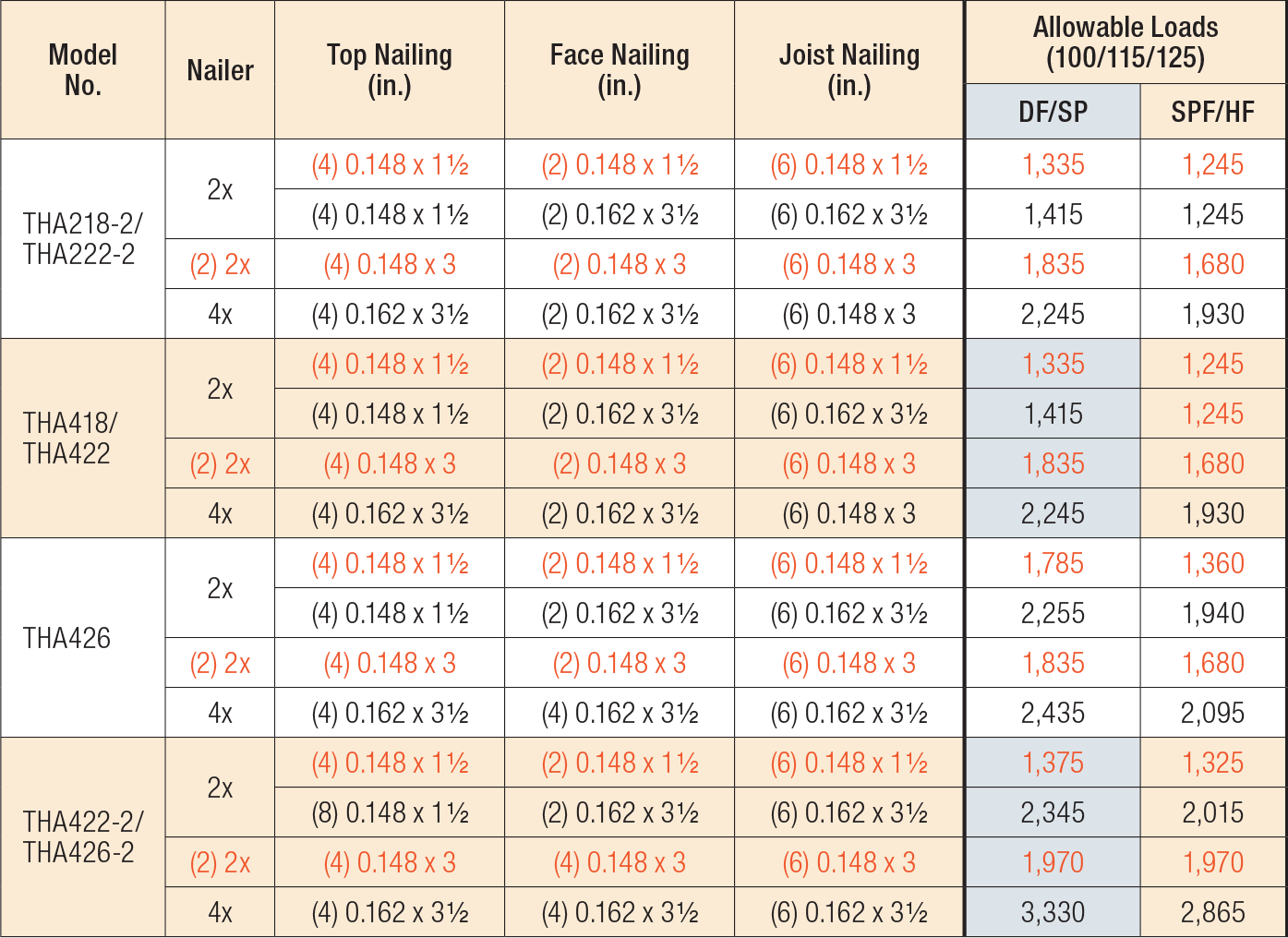

Nailer Table

- Loads for 2x Nailers are applicable to single 4x2 top chord carrying members provided the hanger is located at a top chord panel point and there is no splice at that panel point location.

- Attachment of nailer to supporting member is the responsibility of the Designer.

- Refer to table above for hanger dimensions, minimum top flange requirements and additional footnotes.

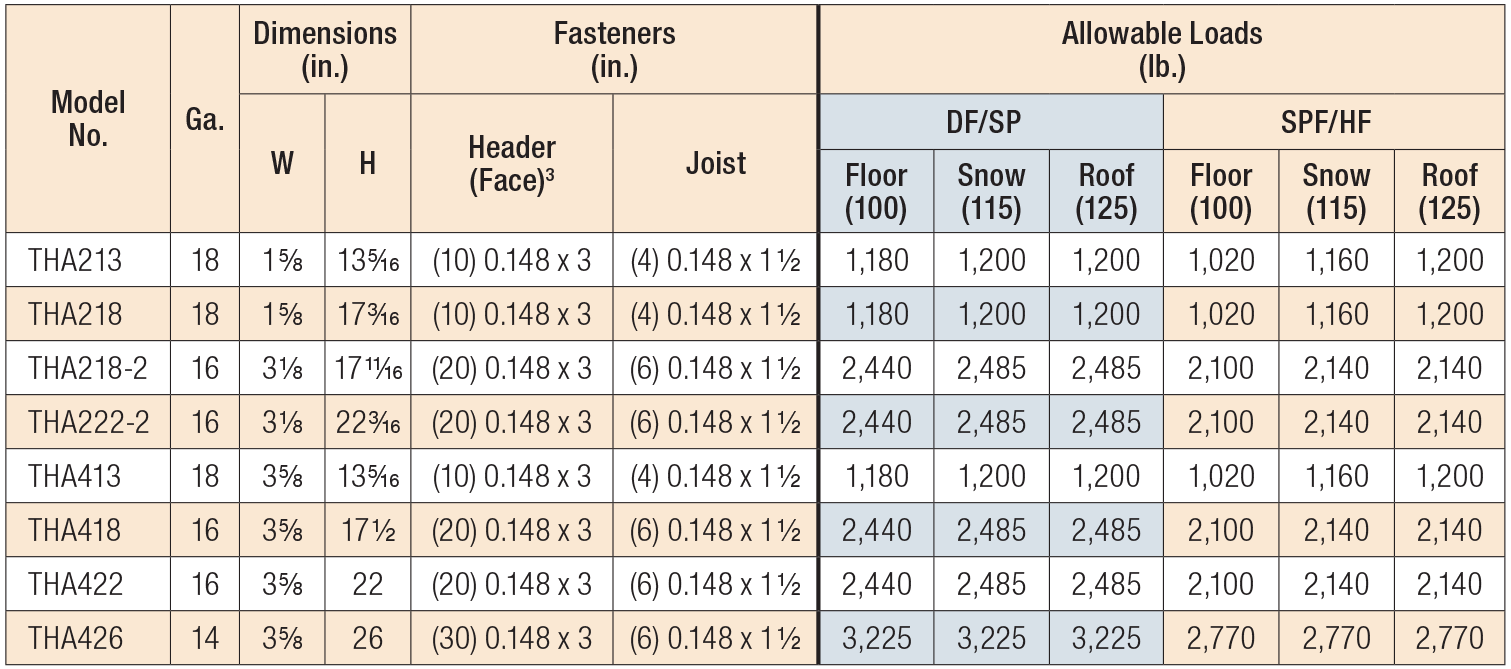

Allowable Loads for Face-Mount (Min.) Nailing Installation

- Loads are based on a min. 2-ply 2x carrying member. 0.148" x 2 1/2" nails may be used instead of the specified 10d commons at 1.00 of the table load. For single-ply 2x or 1 3/4" wide carrying members, use 0.148" x 1 1/2" nails and use 0.77 of the table value. Alternately, SD #9 x1 1/2" screws may be used in place of the specified header and joist nails for full table loads.

- The joist nails should be installed straight into the carried member by straightening the THA double shear nailing tabs. When used to support 2x4 joists, the THA213 or THA218 may be installed with (2) 0.148" x 1 1/2" nails into the joist (one each side).

- At least half of the face fasteners must be installed into the upper half of the header, unless some other means of mechanical reinforcement is used to resist the tension perpendicular to grain stresses. Nails must have a minimum 1/2" edge distance.

- For installations with fewer face fasteners than specified, reduce the allowable load as follows:

Allowable load = No. of Face Nails Used/No. Face Nails in Table x Table Load - Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

Extra Information

Brand:

Simpson Strong-Tie

Weight:

0.80 LBS