Description

These high-capacity, welded hangers are designed for attaching multi-ply girder trusses. The THGB series offers optional installation with Strong-Drive® SDS Heavy-Duty Connector screws, and the bolted THGBH and THGW hangers offer higher design loads. See the THGQ/THGQH series for a lower-cost alternative that uses Strong-Drive SDS Heavy-Duty Connector screws instead of bolts and offers high-load capacities.

Material

- 3 gauge

Finish

- Simpson Strong-Tie gray paint

Installation

- Use all specified fasteners; see General Notes

- All multiple members must be fastened together to act as a single unit

- Maximum 11 7/8" bottom chord in the carrying member to allow for the minimum bolt end distance

- Bolts must be installed symmetrically when using fewer than eight bolts on the eight-bolt backplate

- Girders must be adequately laterally braced to prevent excessive displacement due to secondary torsional stresses (Ref ANSI/TPI 1-2014 Section 7.5.3.5)

Options

Skewed Seat

- THGB/THGBH hangers can be skewed to a maximum of 45°. The maximum allowable down load and uplift load for skew is 0.87 of the table load.

Dropped Bucket

- THGB/THGBH backplates can be extended to allow for up to a 6" dropped bucket.

- Allowable loads are 100% of the table loads.

- Order as “X” version, specify the total backplate height, BK_PLT, equal to the hanger height (H) plus the dropped bucket amount (db). Ex: a THGBV3.62 /9 with a 4" dropped bucket would have a total backplate height of 27 1/4".

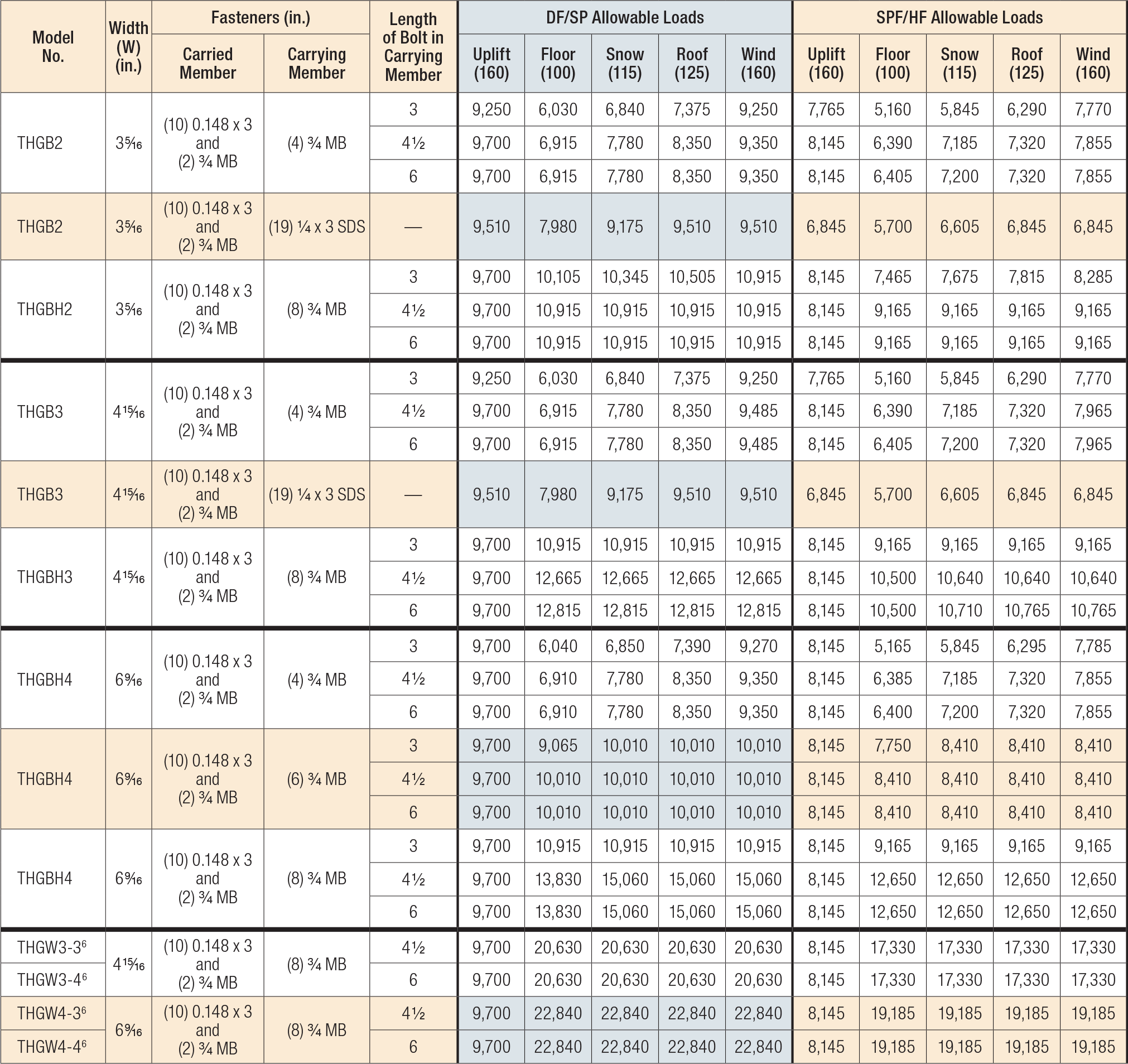

Load Tables

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- A three-ply carrying member is required for the THGW3-3 and THGW4-3; a four-ply carrying member is required for the THGW3-4 and THGW4-4. For all other models, a minimum two-ply carrying member is required.

- Strong-Drive® SDS Heavy-Duty Connector screws require a minimum two-ply (3") carrying member.

- Bolts and Strong Drive® screws may be installed through metal truss connector plates as approved by the Truss Designer, provided the requirements of ANSI/TPI 1-2014, Sections 7.5.3.4 and 8.9.2 are met.

- (10) 0.148" x 3" nails for the carried member will achieve the maximum downloads. Uplift loads are 2,570 lb. for DF/SP and 2,210 lb. for SPF/HF. To achieve maximum uplift, install nails and bolts listed in the table.

- Loads for THGW models require that the supported member have minimum 2x6 end verticals to ensure end-grain bearing. Contact Simpson Strong-Tie for loads when horizontal members are bearing in the hanger seat.

- Wind (160) is a download rating.

- To achieve published loads, install bolts into the girder truss with the nut on the opposite side of the hanger with a standard-cut washer (except THGWs). Standard-cut washers are required for THGB and THGBH.

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

Extra Information

Brand:

Simpson Strong-Tie

Weight:

22.00 LBS